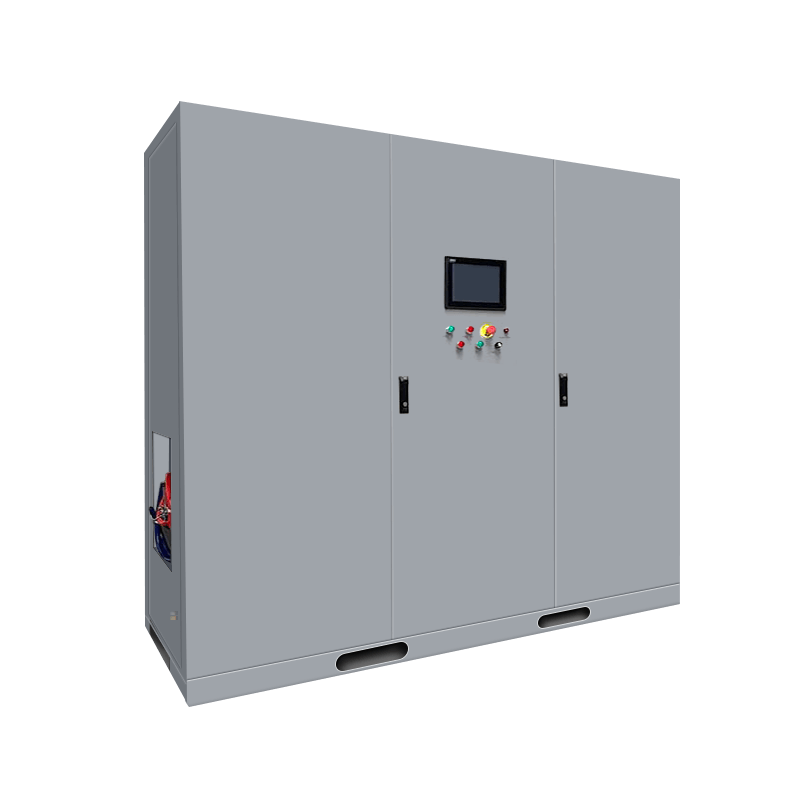

Feature:

- MOSFET Inverter technology achieve ultra high frequency 50kHz-300kHz.

- IGBT wave chopping

- 100% load duration, 24-hour operation under maximum power;

- Power output regulation of Induction Equipment can be controlled by power or current.

- Working condition display: output power, frequency, current and voltage

- 正確な加熱: Power control from 0-100%

- Working mode can be Automatic, Manual, Temperature Control (Optional)

- 包括的な保護: Over current, over Temperature, Lack of water, Over Voltage, Phase Loss, Overheat.

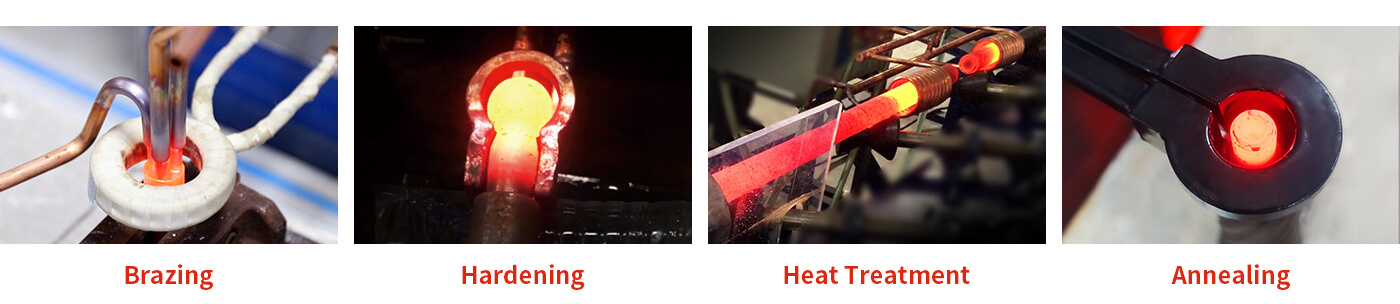

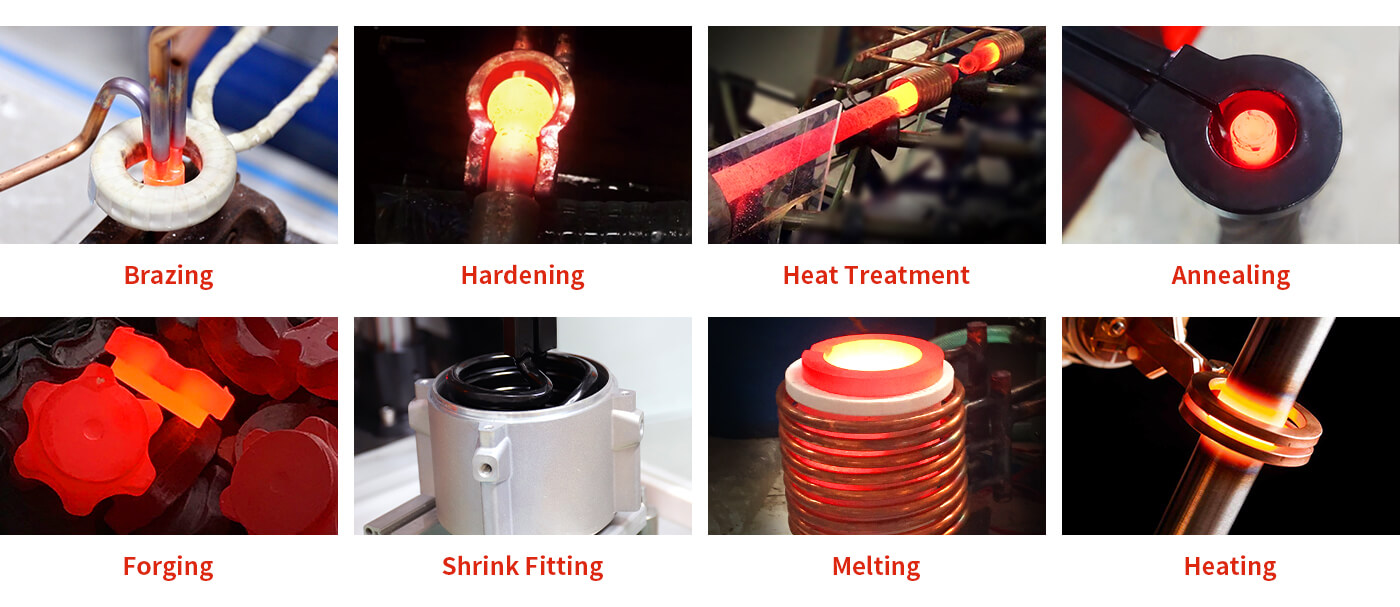

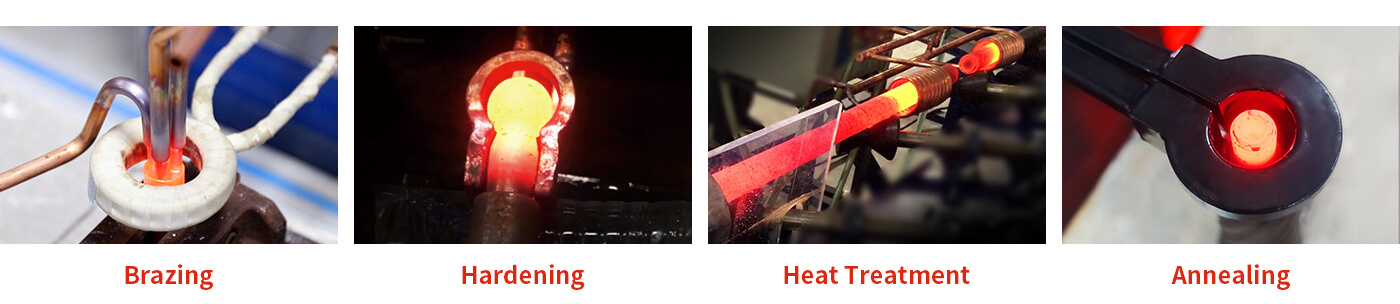

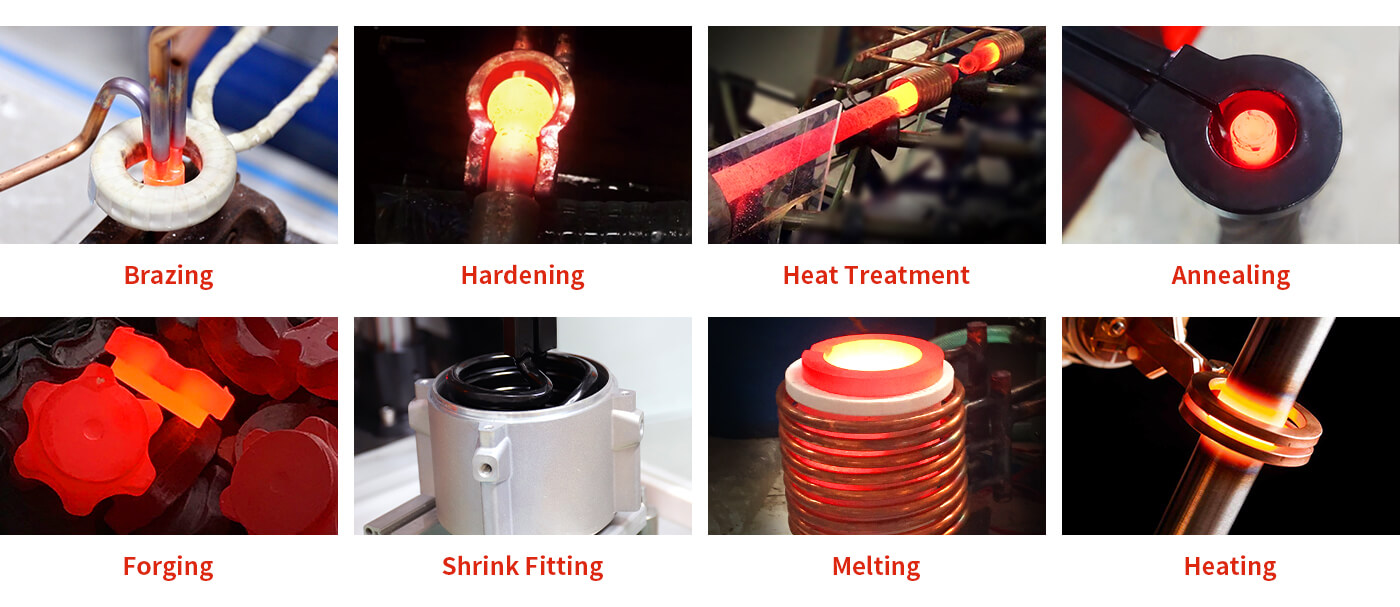

応用

高周波ろう付け, シュリンクフィッティング, 高周波焼き入れ, 鍛造 & 形にする, 誘導アニーリング, 誘導溶解, Induction Coating.

Advantages

- Ultrahigh frequency (60kHz-200kHz), particularly suitable for small size workpieces heating. Ultra-fine metal in diameter 0.1mm can be brazing.

- Auto frequency scanning let induction heating unit work at high efficiency.

- Heating of Induction Device reliable and stable

- Heating without vibration, ensure accurate heating position.

お客様

アプリケーション:

Ultra high frequency induction heating equipment is mostly used for surface quenching of industrial metal parts. It is a metal heat treatment method that generates a certain induction current on the surface of the workpiece, rapidly heats the surface of the part with high frequency and then rapidly quenches it. Ultrasonic frequency induction heating equipment, that is, equipment for induction heating of workpieces for surface quenching.

(1) Heat treatment of parts such as pinions and small shafts

(2) carbon steel screws and stainless steel screws heating viscose

(3) Maglev melting for schools and research institutes

(4) Smelting of crushed or powdered materials

(5) Copper pipe joint welding, 等.

- 誘導加熱機の選択方法?

ワークピースの寸法と加熱領域を教えてください, 加熱温度と加熱時間, 加熱プロセスの特定の要件と同様に, 私たちの経験販売は、適切な誘導暖房装置を推奨します.

- 購入誘導ヒーターの前に暖房テストを見ることができますか?

税関は、私たちの研究室での暖房試験のためにワークピースを私たちに送ることができます, 暖房テストのビデオとレポートを受け取った後にHCGP誘導マシンを購入するかどうかを判断します.

- 設置と手数料のサービスはどうですか?

インストールと委員会の詳細マニュアルと写真とビデオを使用して、お客様に送信されます. ほとんどのお客様は、私たちの指示に従うことで、自分でインストールと手数料を完了できます. 有料のオンサイトインストールサービスを提供しています.

- オペレーションマニュアルは、一般的な過失を処理するための定期的なメンテナンスとガイダンスのための作業基準を提供します. また、スペアパーツの在庫を管理するのにも役立ちます.

- マシンが問題を獲得したときにどのように顧客がサービスを受けることができますか?

7を提供します×24 オンライン技術サポートと修理サービス、およびオンサイトサービス.

- 長い間修理部品を提供できますか?

はい, お客様がスペアパーツインベントリを管理するのを支援します.

- Can you help us design coilfor our new produces?

さまざまなコイルサービスを提供しています:

- 購入前の暖房テストを備えたコイル設計,

- 誘導機器を購入する際のさまざまな暖房ワークのコイルデザイン

- 顧客が新製品を開発するときのコイルデザイン

- 自分でコイルを作るように顧客を導きます

誘導加熱コイル

パッケージの詳細:

1. 輸出用木製ケース

2. 傷を防ぐ粘着ラップ

3. 機械をまとめるためのプラスチックフィルム

4. 揺れを防ぐフォームプレートとブロック

5. 他の顧客の要求

香港の高頻度

香港の高頻度