Особенность:

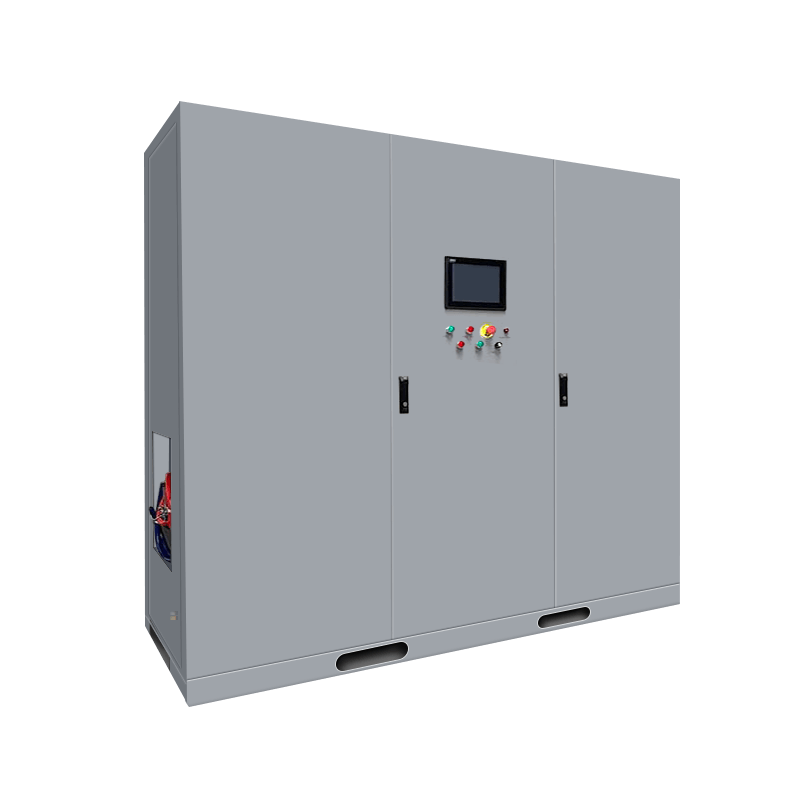

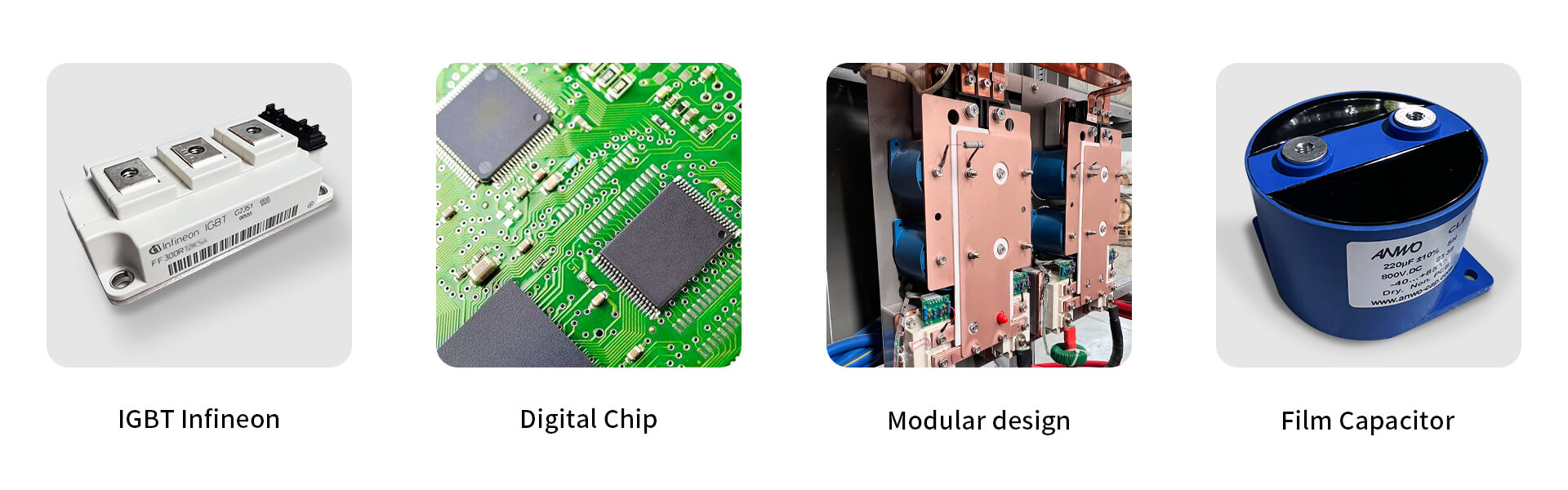

- Высокая эффективность благодаря инверторной технологии IGBT & Резонансная схема серии LC, повышает высокую эффективность.

- Цифровые чип -технологии, Управление выходной мощностью и обнаружение неисправностей полностью сделано с помощью цифрового управления чипами, Значительно уменьшая изменения мощности или неисправности, вызванные факторами окружающей среды и временем использования. This significantly enhances the reliability and stability of the equipment.

- Модульный дизайн, с 80% компонентов в группах модулей, Позволяет соблюдать группы модулей по всем моделям, Сделать техническое обслуживание и ремонт простым и удобным, При сохранении низких затрат.

- Automatic frequency tracking technology enables devices to operate at the optimal frequency state. The working status of the equipment is automatically detected

- Reserve AD, DA interfaces to provide analog signal transmission, while also supporting digital signal transmission using the MODBUS protocol, RS-485. Induction heater is enables easy integration with PLC, ЧПУ-управление, and compatible equipment, allowing for seamless automation control.

- Индукционный генератор HCGP может быть спроектирован как субгармонический резонанс в соответствии с формой и материалом заготовки. Subharmonic resonance technology allows induction power supply to have a wide range of impedance matching, Индукционный нагреватель может работать с различными катушками при оптимальной работе во время нагрева не магнитных и нерегулярно формированных заготовков при высокой эффективности нагрева.

Преимущество:

- Энергетическая экономия 10%-30% comparing with SCR Transistors induction generator.

- Высокая эффективность нагрева повышает урожайность производства.

- Простой и практическое проектирование оборудования, высокая экономическая эффективность.

- Индукционный преобразователь начинает нагрев при любых условиях нагрузки и работает при полной нагрузке в течение 24 часы.

- Комплексная функция защиты обеспечивает высокую надежность индукционного оборудования.

- Обеспечить многочисленную передачу сигнала, такие как импульсный сигнал, цифровой сигнал, RS-485 и т. Д., Индукционный нагреватель HCGP легче интегрировать с другой машиной и достичь автоматизации производства.

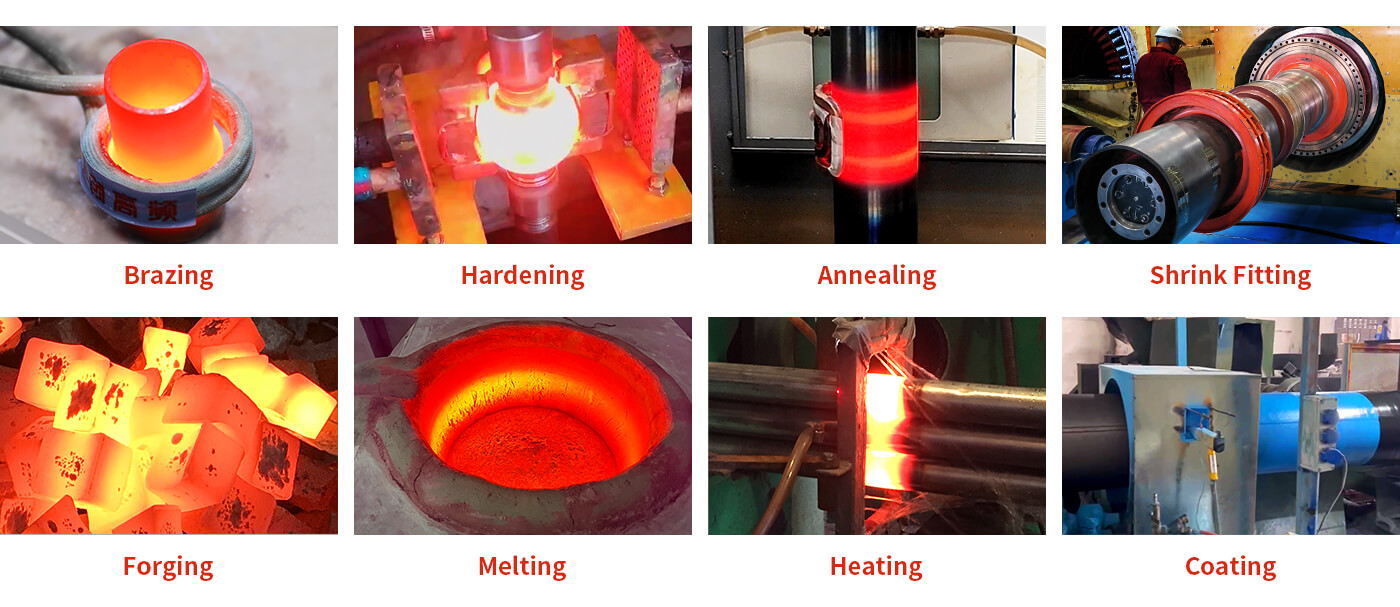

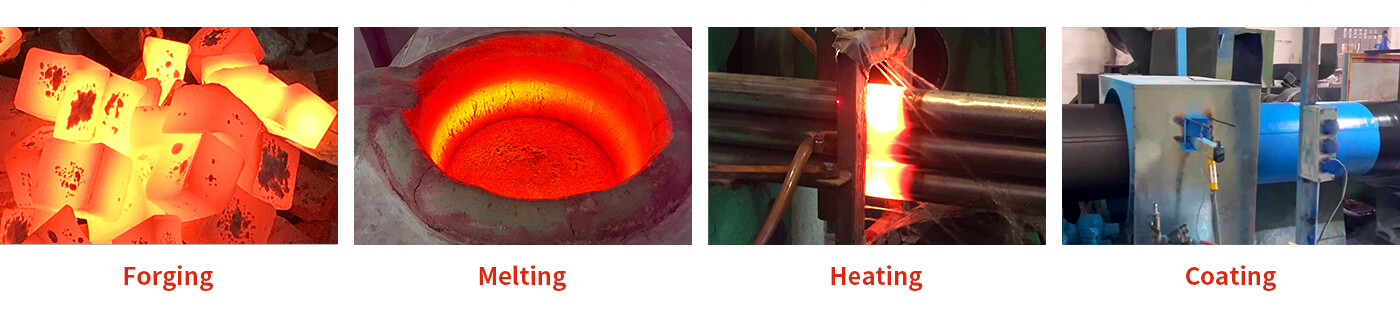

Приложения

Индукционная ковка & Формирование, Индукционная пайка, Сокращение, Индукционное упрочнение, Индукционная термообработка, Индукционная плавка, Индукционное покрытие

Наши клиенты

Хунчуанская высокая частота

Хунчуанская высокая частота