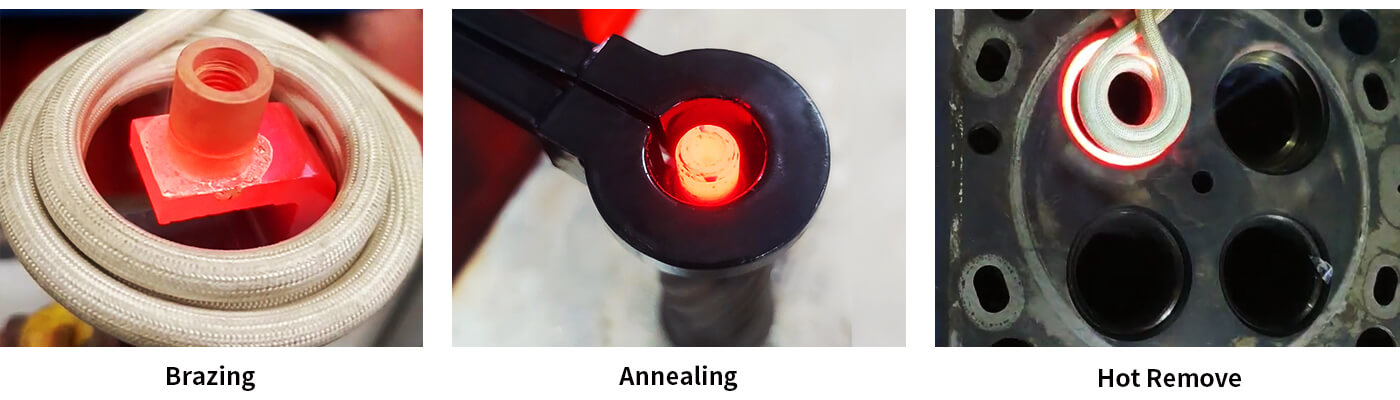

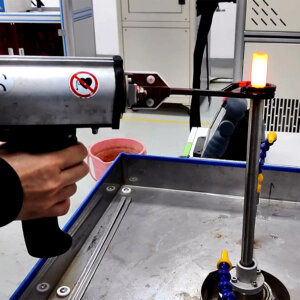

O equipamento de aquecimento de indução móvel é um design especial para aquecimento flexível na brasagem, encolhimento de encolhimento, recozimento, Remova a quente, por aquecimento etc..

Vantagens:

1. The handheld machine can realize induction brazing on complex and inaccessible workpieces or workshop locations. It is small, space-saving, easy to move, and simple to operate.

2. There is no need to transport batches of workpieces or store them near the brazing equipment during brazing, making it an ideal choice for online brazing.

3. More comfortable working environment. The working environment of flame heating is harsh, thus reducing the operator’s work enthusiasm and production efficiency, while induction heating is quiet and comfortable and will not cause the surrounding environment to heat up.

4. The controllability and precise heat transfer of induction heating reduce the risk of overheating to the greatest extent, thereby avoiding damage to the heated workpiece and reducing loss.

5. High frequency, stable heating output, no vibration during heating operation, ensuring accurate welding position, and can weld extremely fine metals with a minimum diameter of 0.1mm. Sensors can be customized according to different shapes of workpieces.

6. Reduce costs: An efficient and precise heating process means you can get things done right the first time. Minimize scrap, rework and energy consumption.

Aplicativo:

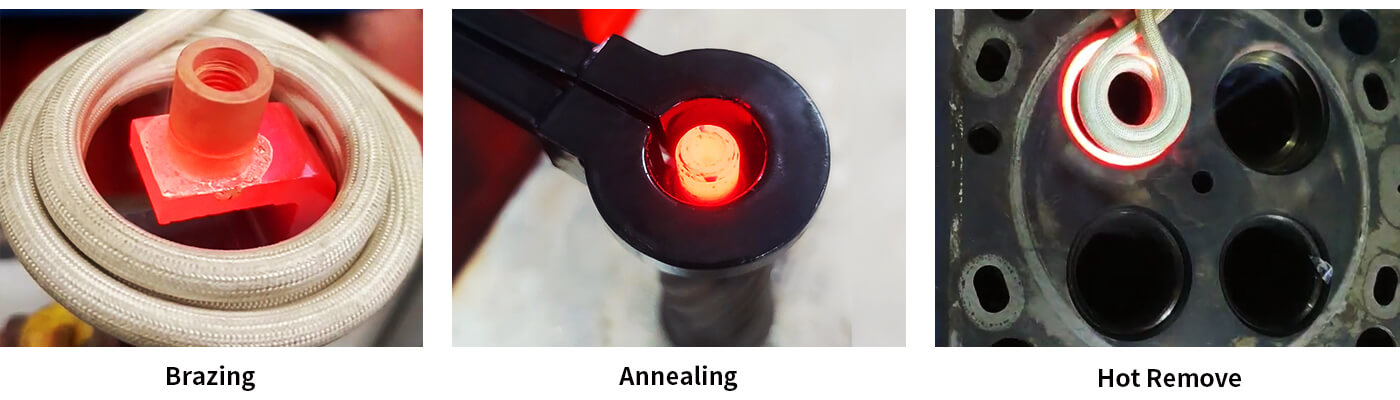

Brasagem por Indução, Induciton Annealing, Induction preheating, Induction shrink fitting, Hot remove

Nossos clientes

Aplicativo

O dispositivo de aquecimento de indução potável é amplamente aplicado em indústrias como refrigeração e hvac, Aparelhos domésticos, Fabricação de automóveis, Motor elétrico, and medical devices.

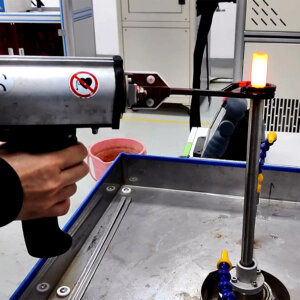

Hand-holding Induction Brazing

Mobile Induction Heating

Brasagem por Indução

Portable Induction Heating

1. Como escolher a máquina de aquecimento por portátil?

Informe-nos as dimensões e a área de aquecimento da peça de trabalho, temperatura de aquecimento e tempo de aquecimento, bem como qualquer requisito específico do processo de aquecimento, nossa experiência em vendas recomendará o equipamento de aquecimento por indução apropriado.

2. Podemos ver o teste de aquecimento antes de comprar o aquecedor por indução?

A alfândega pode nos enviar a peça para testes de aquecimento em nosso laboratório, e decida se comprar a máquina de indução HCGP após receber o vídeo de teste de aquecimento e relatório.

3. Que tal o serviço de instalação e comissionamento?

O manual detalhado e guia para instalação e comissionamento com foto e vídeo serão enviados aos nossos clientes. A maioria de nossos clientes pode concluir a instalação e o comissionamento por conta própria, seguindo nossas instruções. Ainda oferecemos serviço pago de instalação no local.

4. O manual de operação fornece padrões de trabalho para manutenção regular e orientação para lidar com falhas comuns. também ajudamos você a gerenciar seu estoque de peças de reposição.

5. Como o cliente pode obter atendimento quando a máquina apresenta problemas?

Fornecemos 7x24h Online Technical Support and Repair Service, bem como serviço no local.

6. Você pode fornecer peças de reparo por um longo tempo?

Sim, ajudaremos nosso cliente a gerenciar seu estoque de peças de reposição.

7. Você pode nos ajudar a projetar bobina para nossos novos produtos?

Oferecemos diferentes serviços de bobina de indução:

- Projeto de bobina de indução com teste de aquecimento pré-compra

- Projeto de bobina de indução para diferentes peças de trabalho ao comprar equipamentos de indução

- Design de bobina de indução para os clientes ao desenvolver novos produtos

- Orientar os clientes para fazer bobinas de indução por conta própria

Bobinas de aquecimento por indução

Hongchuang alta frequência

Hongchuang alta frequência