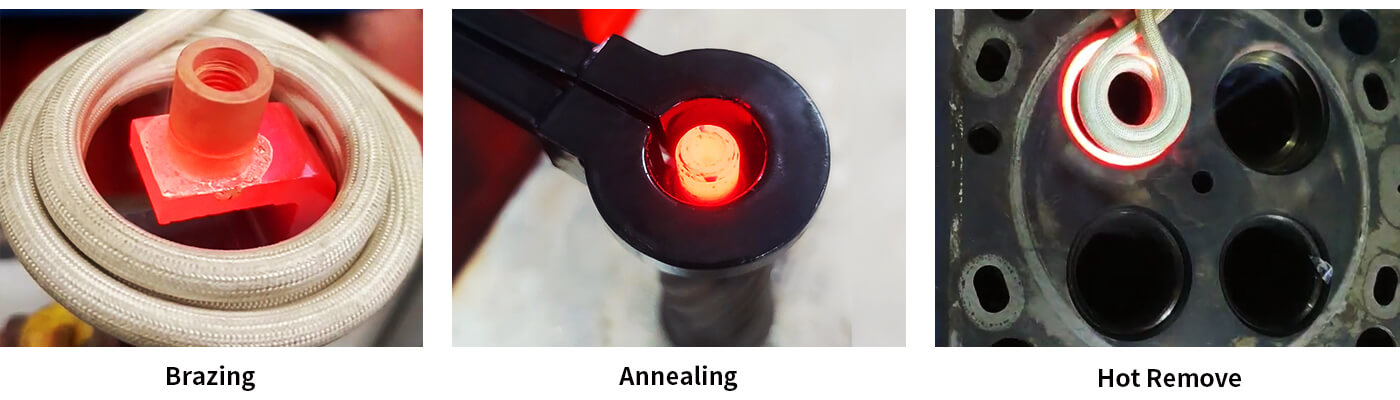

Mobile Induction Heating Equipment is special design for flexible heating in brazing, menyusut pas, annealing, hot remove, per-heating etc.

Advantages:

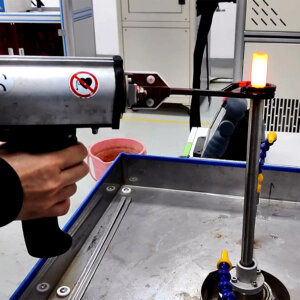

1. The handheld machine can realize induction brazing on complex and inaccessible workpieces or workshop locations. It is small, space-saving, easy to move, and simple to operate.

2. There is no need to transport batches of workpieces or store them near the brazing equipment during brazing, making it an ideal choice for online brazing.

3. More comfortable working environment. The working environment of flame heating is harsh, thus reducing the operator’s work enthusiasm and production efficiency, while induction heating is quiet and comfortable and will not cause the surrounding environment to heat up.

4. The controllability and precise heat transfer of induction heating reduce the risk of overheating to the greatest extent, thereby avoiding damage to the heated workpiece and reducing loss.

5. High frequency, stable heating output, no vibration during heating operation, ensuring accurate welding position, and can weld extremely fine metals with a minimum diameter of 0.1mm. Sensors can be customized according to different shapes of workpieces.

6. Reduce costs: An efficient and precise heating process means you can get things done right the first time. Minimize scrap, rework and energy consumption.

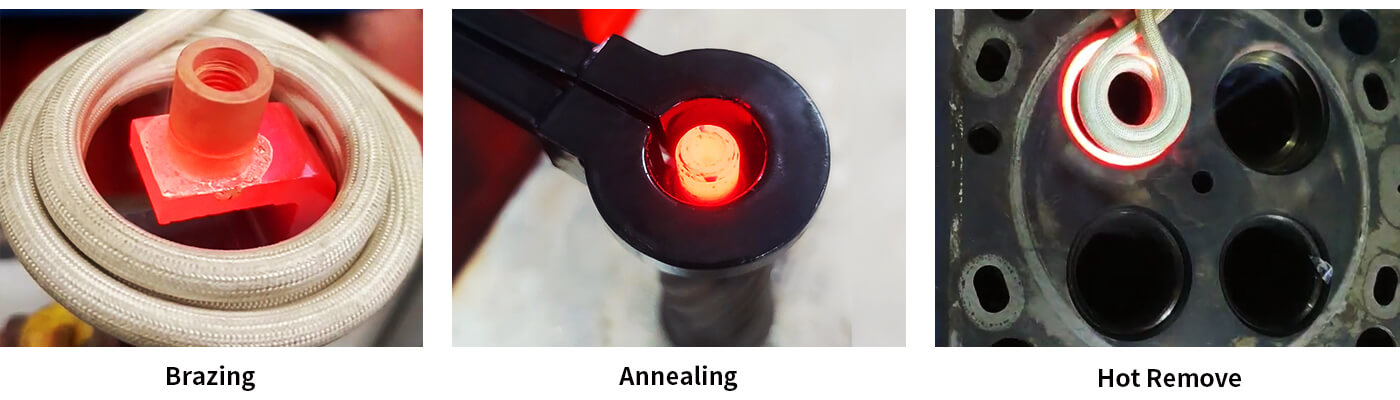

Application:

Pematrian Induksi, Induciton Annealing, Induction preheating, Induction shrink fitting, Hot remove

Our Customers

Application

Potable induction heating device is widely applied in industries such as refrigeration and HVAC, peralatan Rumah Tangga, automobile manufacturing, motor listrik, and medical devices.

Hand-holding Induction Brazing

Mobile Induction Heating

Pematrian Induksi

Portable Induction Heating

1. How to choose the portable induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. The operation manual provides work standards for regular maintenance and guidance for dealing common fault. we also help you manage your spare parts inventory.

5. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

6. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

7. Can you help us design coil for our new produces?

We offer different induction coil service:

- Induction Coil design with pre-purchase heating testing

- Induction Coil design for different heating workpieces when purchasing induction equipment

- Induction Coil design for customers when they developing new products

- Guide customers to make induction coils on their own

Induction Heating Coils

Frekuensi Tinggi Hongchuang

Frekuensi Tinggi Hongchuang