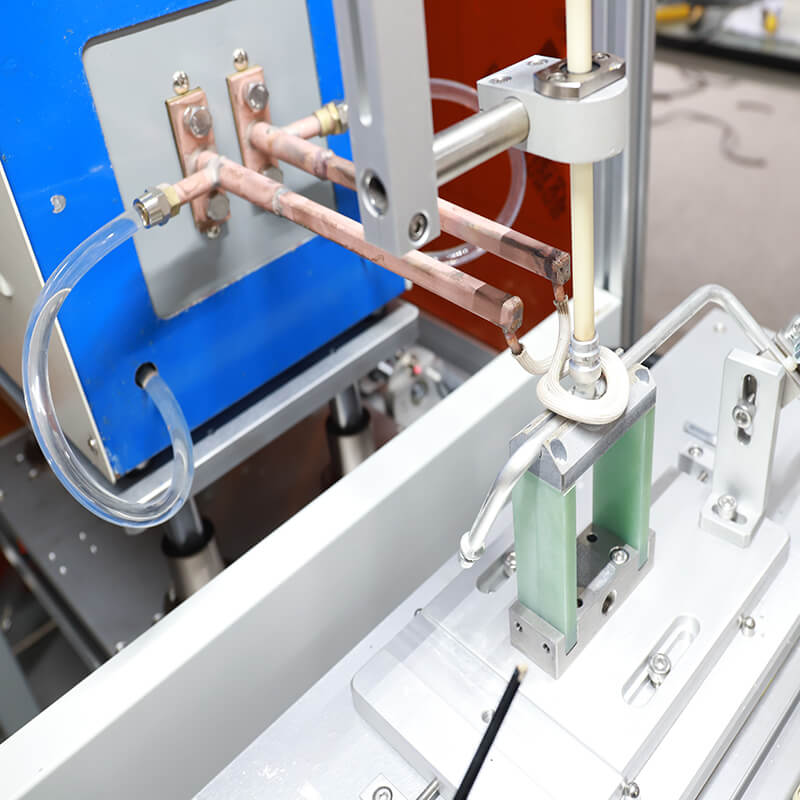

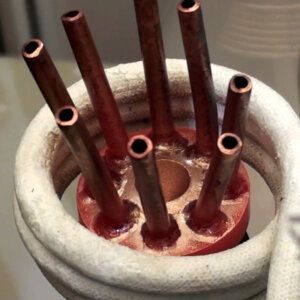

This Induction brazing machine is Integrated design with manual feeding, automatic brazing, nitrogen protection during the brazing process, automatic cooling, and manual unloading. Two brazing stations increase production throughput.

Feature:

- Induction brazing machine can be manual, semi-automatic or automatic according to customer’s need.

- Working station of induction tube brazing machines are customized single station, two stations and multiple stations to meet different production rate requirement.

- PLCcontrol let induction brazing machine easy to integrated with production line.

- Particularlydesign ensure successful brazing process such as inert gas for operation shield, air cooling, flux addition, fixture design for accurate heating location, cleanliness, process control, 等.

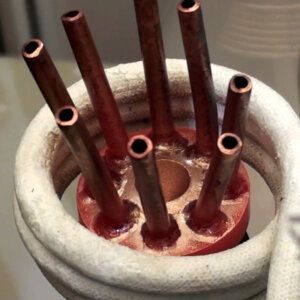

- Induction coil will be design regarding to pipe material, size and joint place.

応用

アドバンテージ

- Precise, targeted heatingincrease production output

- Reliable and accurate heating ensure consistent braze qualityevery time.

- Induction heating isnone contact heating without flame or hot furnace, provide safety working environment.

- Integrated induction Brazing Machine save space in work shop.

Our Clients

Induction Brazing Equipment can be customized design for various brazing processes, such as air conditioning refrigeration valve components, refrigerator/freezer tubing components, solar energy fittings, compressor parts, washing machines (pipe-to-pipe connections, pipe-to-shell connections, pipe-to-valve connections), automobile evaporators, compressor connections, short-circuit rings on motors, and other brazing processes.

Aluminum Pipe-joint Brazing

Copper-Silver Brazing

Copper-Stainless Steel Brazing

Copper Brazing

Induction Brazing System is widely applied in industries such as refrigeration and HVAC, household appliances, automotive, 電気モーター, renewable industrial and medical devices.

Industries of Induction Heating applications

1. How to choose the induction heating machine?

ワークピースの寸法と加熱領域を教えてください, 加熱温度と加熱時間, as well as any specific requirement of heating process, 私たちの経験販売は、適切な誘導暖房装置を推奨します.

2. 購入誘導ヒーターの前に暖房テストを見ることができますか?

税関は、私たちの研究室での暖房試験のためにワークピースを私たちに送ることができます, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. 設置と手数料のサービスはどうですか?

インストールと委員会の詳細マニュアルと写真とビデオを使用して、お客様に送信されます. ほとんどのお客様は、私たちの指示に従うことで、自分でインストールと手数料を完了できます. 有料のオンサイトインストールサービスを提供しています.

4. オペレーションマニュアルは、一般的な過失を処理するための定期的なメンテナンスとガイダンスのための作業基準を提供します. また、スペアパーツの在庫を管理するのにも役立ちます.

5. マシンが問題を獲得したときにどのように顧客がサービスを受けることができますか?

7x24hのオンラインテクニカルサポートと修理サービス、およびオンサイトサービスを提供しています.

6. 長い間修理部品を提供できますか?

はい, お客様がスペアパーツインベントリを管理するのを支援します.

7. 私たちの新しいプロデュースのコイルを設計するのを手伝ってくれますか?

We offer different coil service:

- Coil design with pre-purchase heating testing

- Coil design for different heating workpieces when purchasing induction equipment

- Coil design for customers when they developing new products

- Guide customers to make coils on their own

誘導加熱コイル

香港の高頻度

香港の高頻度