Descriptions:

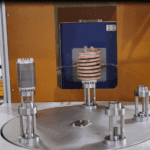

This induction heating machine heats rotors for shrink fitting in rotary index type with multi-stations, manually loading or robot arm loading, automatic feeding and heating with temperature control.

Features:

1. Rotor is heating with induction, precise localize heat meet tight production tolerances.

2. Multi-stations design for more auxiliary process need.

3. Multiple-segment settings for induction heating: There are 5 segment basically and can be customized according to customer requirements.

4. Precise temperature control: In collaboration with the manufacturer,we have jointly developed infrared thermometers with a measurement accuracy of ±1% Measuring range; Closed-loop control system with PID controller, achieving precise temperature control during induction heating process.

5. Accurate heating: Heating time can be accurate to 0.1 seconds.

6. Storan Data: Multiple process parameters storage with one-click for data retrieval

7. Plentiful interfaces: Can be connected to industrial buses such as RS-485, Profibus, CAN etc. HCGP induction heater is easier to integrated with other machine and achieve production automation.

Advantages:

1. Simple Operation and lower requirement on operator

2. Increase products pass rate with precise heating

3. Meet production rate with fast heating

4. Customization available for different type of rotors or similar parts heating.

Aplikasi:

The automatic motor stator hot-assembly equipment is mainly used in the field of motor manufacturing and is an indispensable equipment in the motor manufacturing process. During the motor manufacturing process, the motor stator needs to be positioned and hot-packed to ensure the performance and quality of the motor. The automatic motor stator heat-packing equipment can improve the efficiency and precision of heat-packing, reduce manual operation and work intensity, thereby improving the efficiency and quality of motor production.

Stator and Rotor Assembly

Shrink Fitting Rotor Process

Motor Housing Heating

Induction Shrink Fitting

1. How to choose the portable induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. The operation manual provides work standards for regular maintenance and guidance for dealing common fault. we also help you manage your spare parts inventory.

5. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

6. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

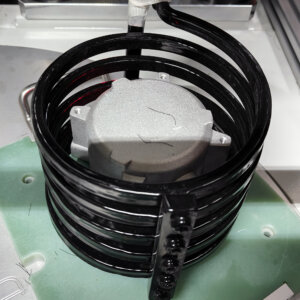

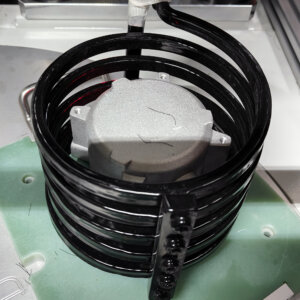

7. Can you help us design coil for our new produces?

We offer different induction coil service:

- Induction Coil design with pre-purchase heating testing

- Induction Coil design for different heating workpieces when purchasing induction equipment

- Induction Coil design for customers when they developing new products

- Guide customers to make induction coils on their own

Packaging Details:

1. Plywood case for export

2. Adhesive wrap to prevent scratches

3. Plastic film to keep the machine together

4. Foam plate and block to prevent shake

5. Other customer’s requirements

Frekuensi Tinggi Hongchuang

Frekuensi Tinggi Hongchuang