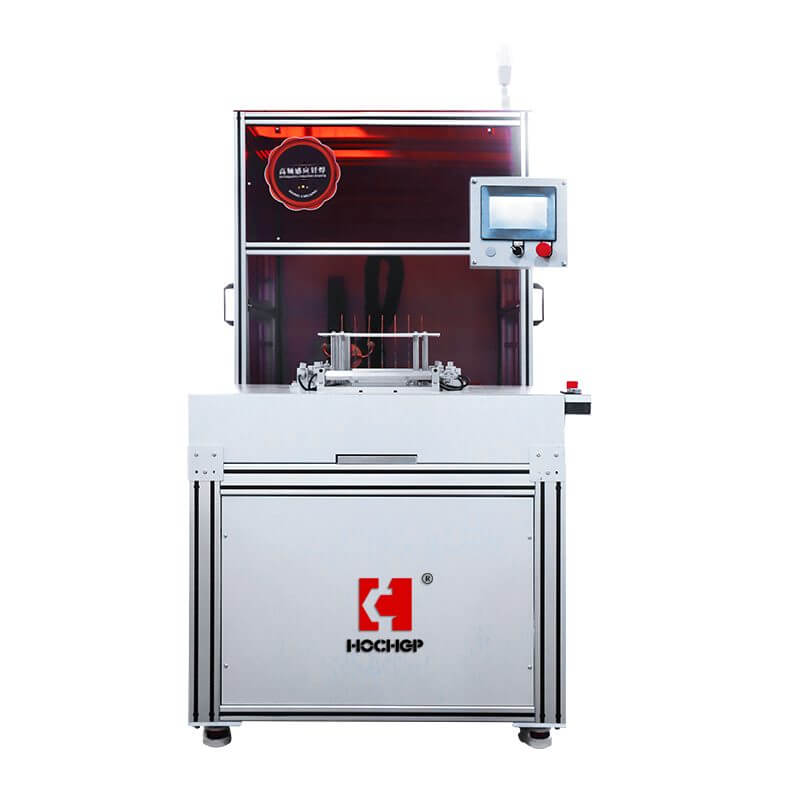

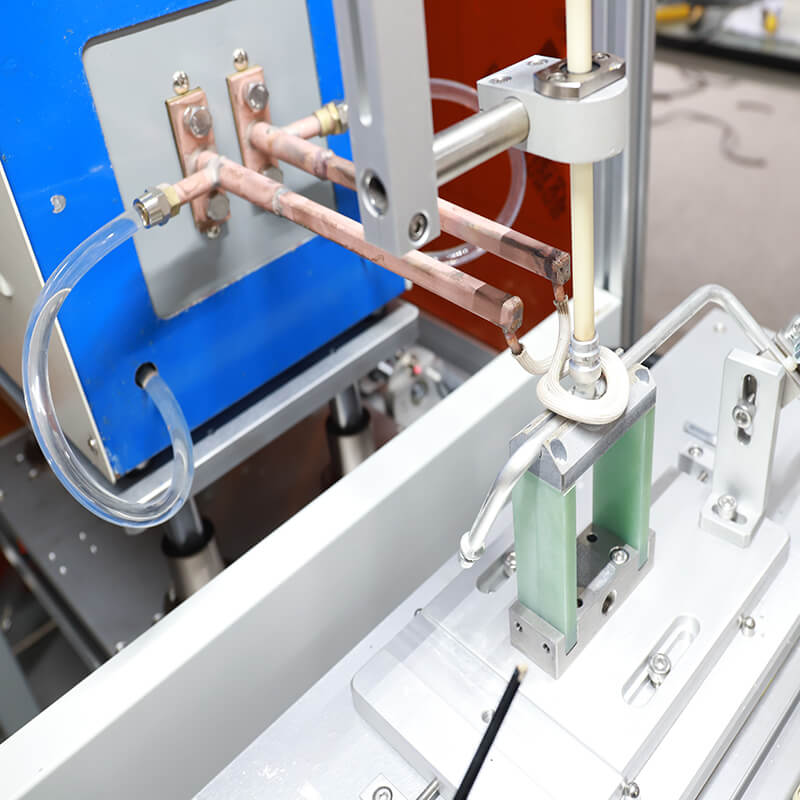

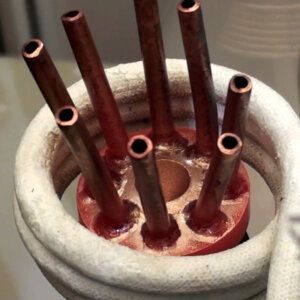

This Induction brazing machine is integrated design with turn-table transmission, automatic brazing, soldering flux feeding automatically during brazing process, automatic cooling, and manual feeding & unloading. HCGP has 20 years experience of induction brazing experience and offer customized automatic system based on variety brazing process and production line.

Features:

- Multiple-segment settings for induction heating: There are 5 segment basically and can be customized according to customer requirements.

- Precise temperature control: Infrared thermometers with a measurement accuracy of ±1% Measuring range, Closed-loop control with PID controller, achieving precise temperature control during induction brazing process.

- Accurate heating: Heating setting time can be accurate to 0.1 초.

- 데이터 저장: Multiplebrazing process parameters storage with one-click for data retrieval

- PLC control with user friendly interface, operation easy without more skill requirement of operator.

- Particularlydesign meet various brazing process such as inert gas for operation shield, air cooling, flux addition, fixture design for accurate heating location, cleanliness, process control, 등.

- Induction brazing system can be linear drive, rotary index type and other types for variety workpieces loading and composite process requirement.

응용

이점

- Precise, targeted heatingincrease production output

- Reliable and accurate heating ensure consistent braze qualityevery time.

- Induction heating is none contact heating without flame or hot furnace, provide safety working environment.

- Compact induction heater save space in work shop.

Our Clients

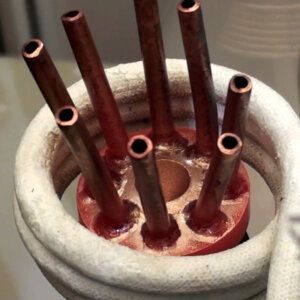

Induction Tube Brazing Machine can be used for various brazing processes, such as air conditioning refrigeration valve components, refrigerator/freezer tubing components, solar energy fittings, compressor parts, washing machines (pipe-to-pipe connections, pipe-to-shell connections, pipe-to-valve connections), automobile evaporators, compressor connections, short-circuit rings on motors, and other brazing processes.

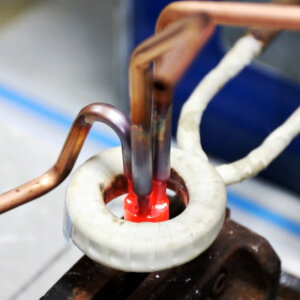

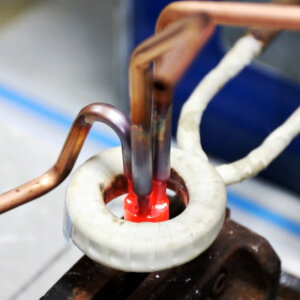

유도 브레이징

Copper Pipe Brazing

Copper-Stainless Steel Brazing

Copper Brazing

Induction Pipe Brazing Machine is widely applied in industries such as refrigeration and HVAC, household appliances, automotive, 전기 모터, renewable industrial and medical devices.

Industries of Induction Heating applications

1. 유도 가열 기계를 선택하는 방법?

가공물의 치수와 가열면적을 알려주세요., 가열 온도 및 가열 시간, as well as any specific requirement of heating process, 우리의 경험 판매는 적절한 유도 가열 장비를 추천합니다.

2. 인덕션 히터 구입 전 가열 테스트를 볼 수 있나요??

세관은 실험실에서 가열 테스트를 위해 공작물을 우리에게 보낼 수 있습니다., and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. 설치 및 커미션 서비스는 어떻습니까??

설치 및 시운전에 대한 자세한 설명서와 가이드는 사진과 비디오와 함께 고객에게 전송됩니다.. 대부분의 고객은 당사의 지침에 따라 스스로 설치 및 시운전을 완료할 수 있습니다.. 우리는 여전히 유료 현장 설치 서비스를 제공합니다.

4. 취급설명서는 정기적인 유지보수를 위한 작업기준과 일반적인 고장처리에 대한 지침을 제공합니다.. 우리는 또한 귀하의 예비 부품 재고 관리를 도와드립니다..

5. 기계에 문제가 생겼을 때 고객은 어떻게 서비스를 받을 수 있나요??

우리는 연중무휴 24시간 온라인 기술 지원 및 수리 서비스는 물론 현장 서비스도 제공합니다..

6. 오랫동안 수리 부품을 제공할 수 있나요??

예, 우리는 고객이 예비 부품 재고를 관리할 수 있도록 도와드립니다..

7. Can you help us design coil for our new produces?

우리는 다양한 코일 서비스를 제공합니다:

- 구매 전 가열 테스트를 통한 코일 설계

- 유도 장비 구매시 다양한 가열 공작물에 대한 코일 설계

- 고객이 신제품을 개발할 때 코일 설계

- 고객이 스스로 코일을 만들도록 안내하십시오.

유도 가열 코일

Hongchuang 고주파

Hongchuang 고주파