Feature:

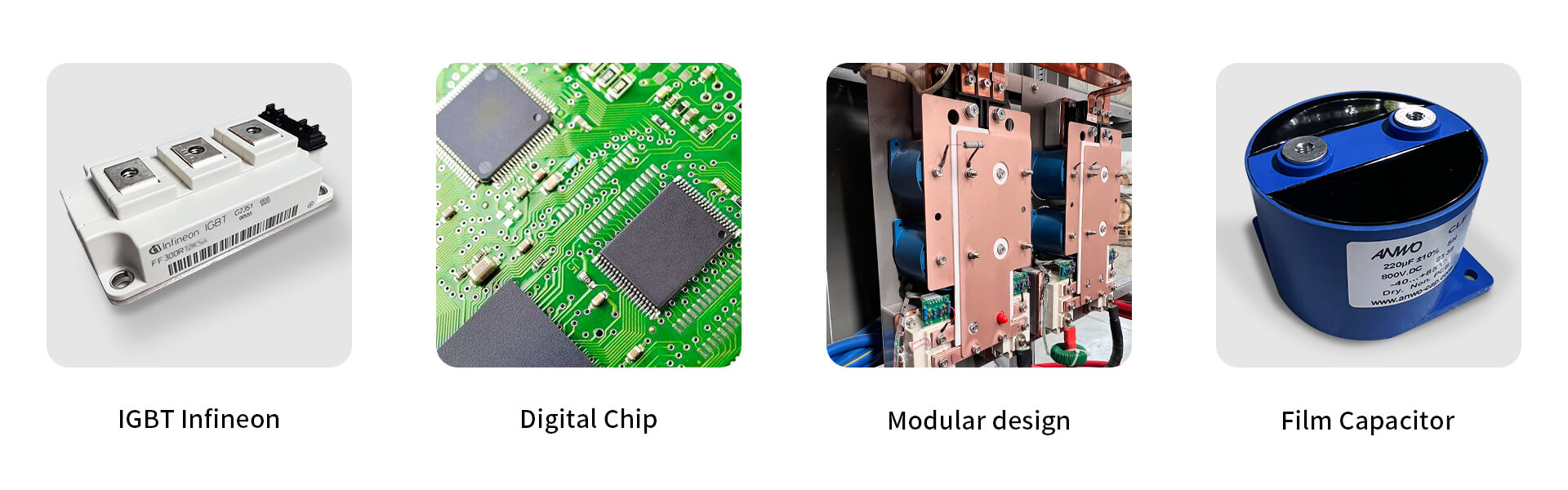

- High efficiency with IGBT inverter technology & LC series resonance circuit, enhances energy saving.

- Digital chip technology, the control of power output and the detection of faults are entirely done through digital chip control, greatly reducing power variations or faults caused by environmental factors and usage time. This significantly enhances the reliability and stability of induction equipment.

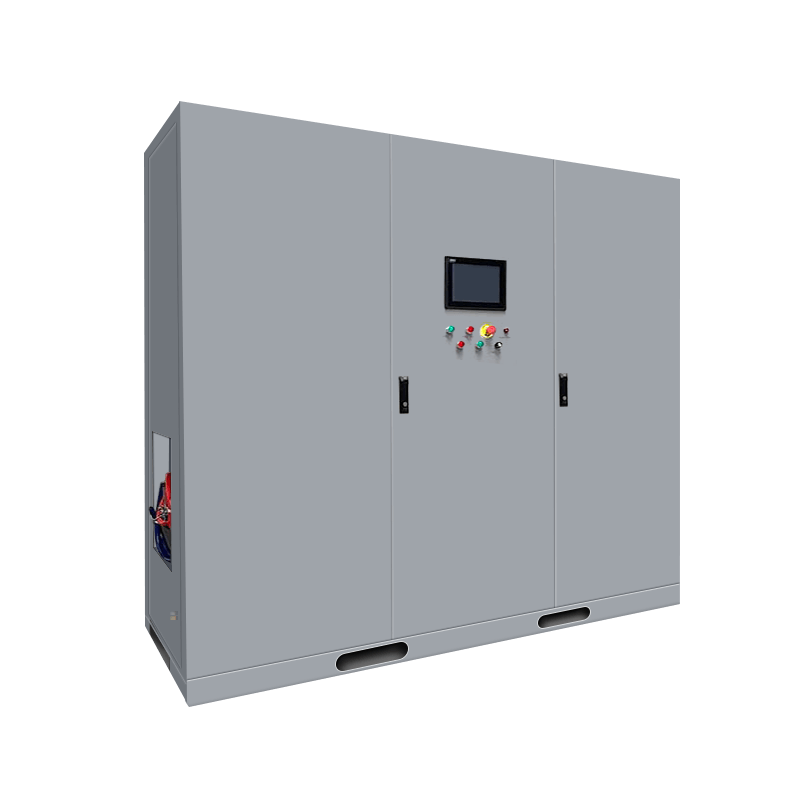

- Modular design, with over 80% of components on module groups, allows for interchangeable module groups across all models, making maintenance and repair simple and convenient, while keeping costs low.

- Automatic frequency tracking technology enables devices to operate at the optimal frequency state. The working status of the equipment is automatically detected

- Reserve AD, DA interfaces to provide analog signal transmission, while also supporting digital signal transmission using the MODBUS protocol, RS-485. Induction heater is enables easy integration with PLC, CNC control, and compatible equipment, allowing for seamless automation control.

- HCGP Induction device can be designed as subharmonic resonance according to shape and material of the workpiece. Subharmonic resonance technology allows induction power supply to have a wide range of impedance matching, induction heater can work with different coils at optimal operation during heating non-magnetic and irregularly shaped workpieces at high heating efficiency.

アドバンテージ:

- Energy saving 10%-30% comparing with SCR Transistors induction generator.

- High heating Efficiency increase production yield.

- Simple and practical equipment design, high cost-effectiveness

- Induction Converter start heating under any load condition and operate at full load for 24 hours.

- Comprehensive the protection function ensuring high reliability of the induction equipment

- Provide multiple signal transmission such as pulse signal, digital signal, RS-485 etc, HCGP induction heater is easier to integrated with other machine and achieve production automation.

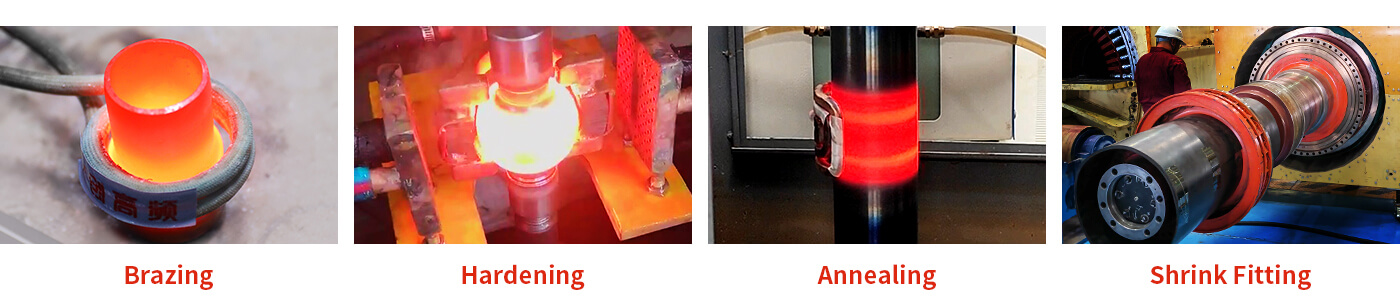

アプリケーション

Induction Forging & 形にする, 高周波ろう付け, シュリンクフィッティング, 高周波焼き入れ, Induction Annealing, 誘導溶解, Induction bending

お客様

香港の高頻度

香港の高頻度