생산 조립 산업

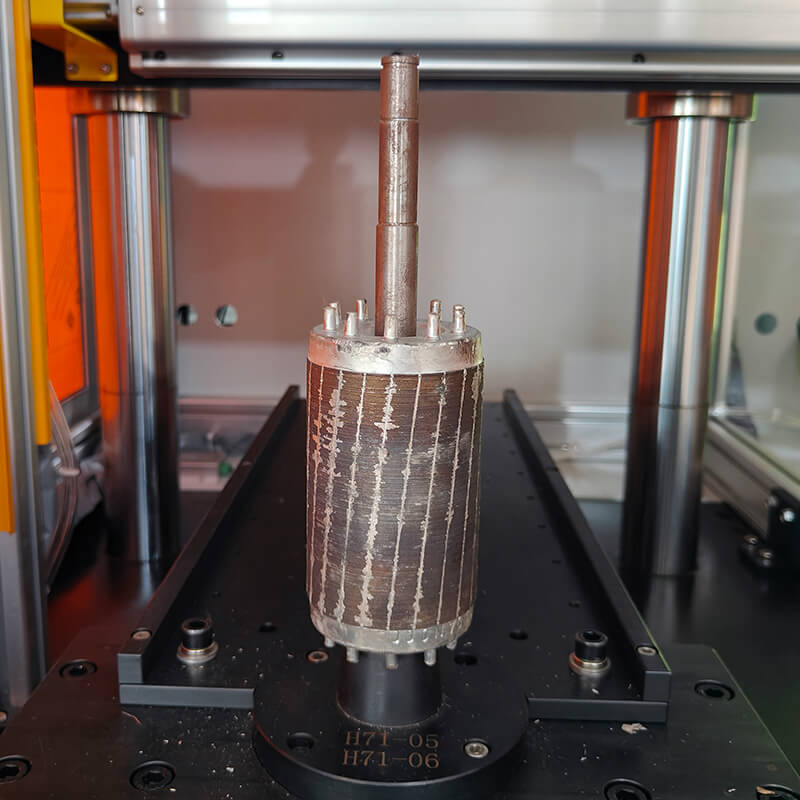

Induction heating represents a valid solution for hot assembly when coupling metal parts, since it allows to compensate interference with thermal expansion and subsequent driving with definitely smaller forces: productive results are significant.

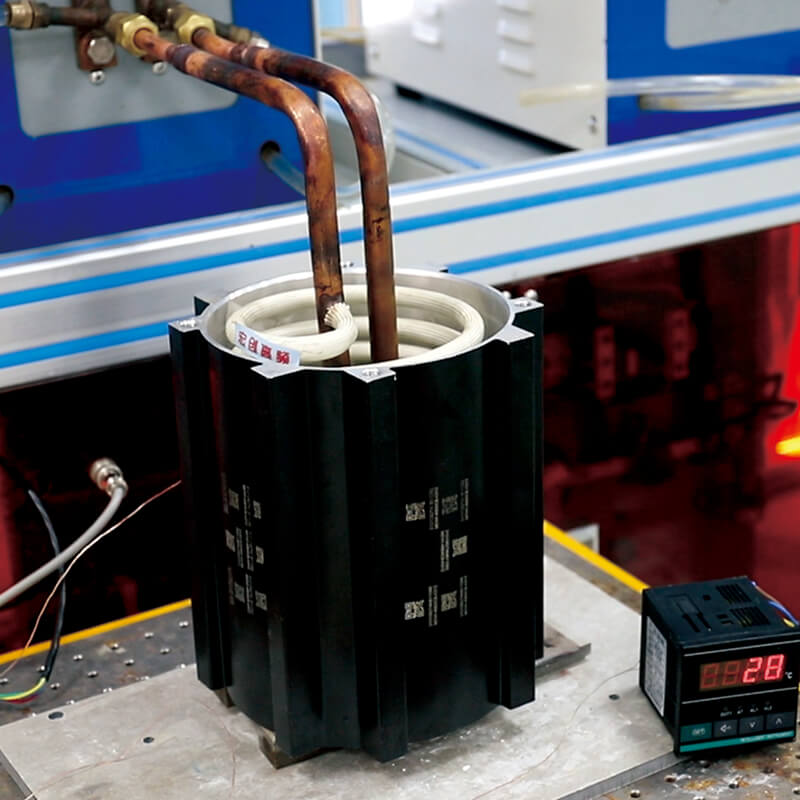

Using induction heating, aluminum housings can be heated very quickly for assembly purposes.

Image Gallery

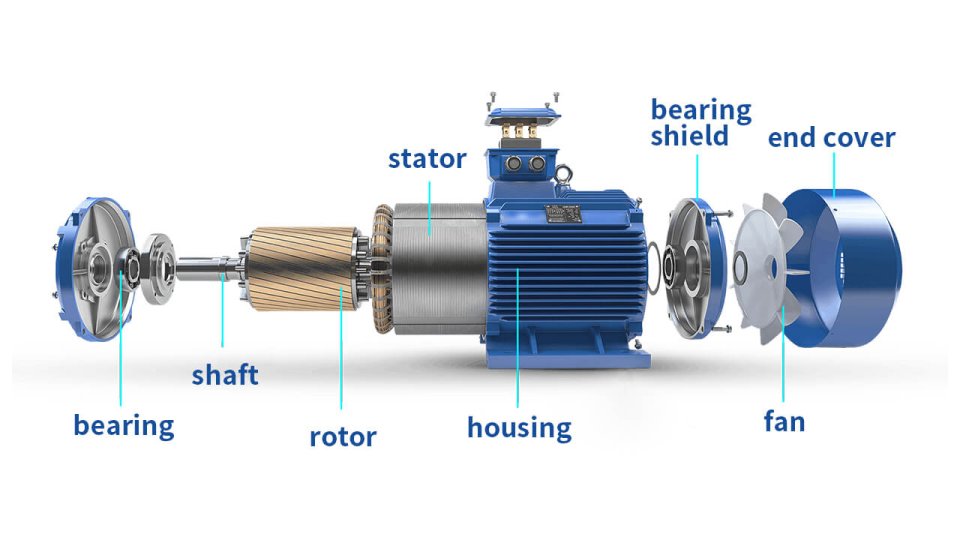

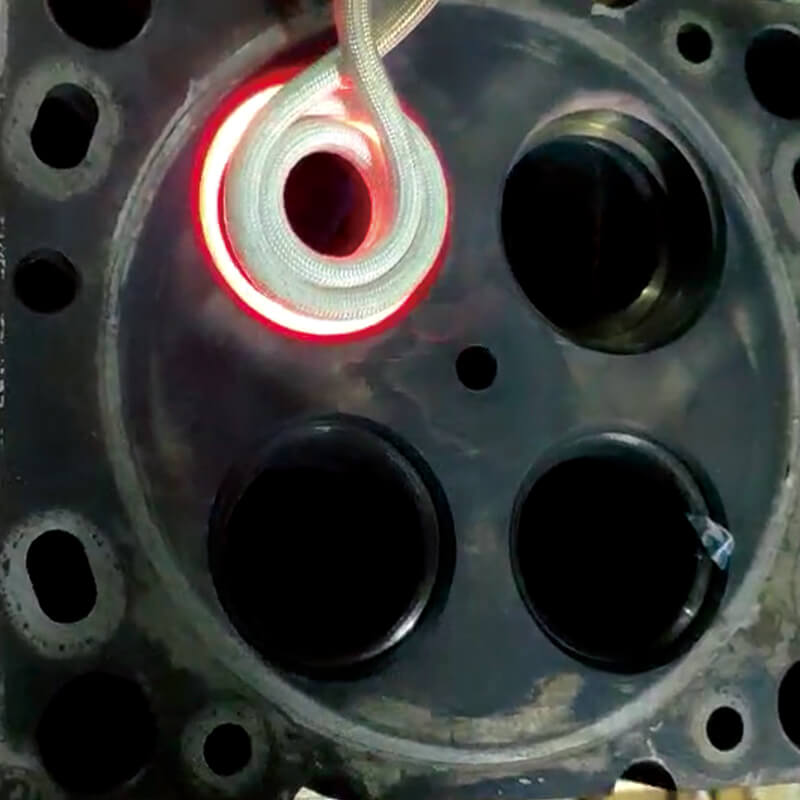

Induction shrink fitting uses for parts fit or remove mainly in the automotive industry and the production of electric motors.

Induction preheating and post heating for welding are used for pipe, plate and other steel welding in vary industries, shipyards, offshore platforms, oil and gas pipelines, thermal power, wind power, 등.

This air cooled induction heaters still can be widely used for shrink fitting, 뜨거운 제거, Straightening, coating, heat treatment.

Hongchuang 고주파

Hongchuang 고주파