Индукционный нагрев: An Efficient Industrial Technology

Induction heating is a highly efficient and flexible technology used in many industries. Unlike traditional heating methods that rely on heat transfer through conduction or convection, induction heating uses electromagnetic fields to directly heat metal objects. This unique process offers several key advantages:

Energy Efficiency

No need for flames or heating elements. Energy transfers directly to the workpiece, reducing heat loss to the environment.

Saves energy and cuts costs.

Precision Heating

Targets specific areas of the workpiece, avoiding unnecessary heating of other parts.

Works quickly, speeding up production and saving time.

Material Protection

Rapid heating reduces exposure to high temperatures, preventing damage like oxidation or warping.

Maintains consistent quality in manufacturing.

Clean & Safe Operation

Non-contact process eliminates contamination risks.

Uses electricity instead of fossil fuels, reducing greenhouse gas emissions.

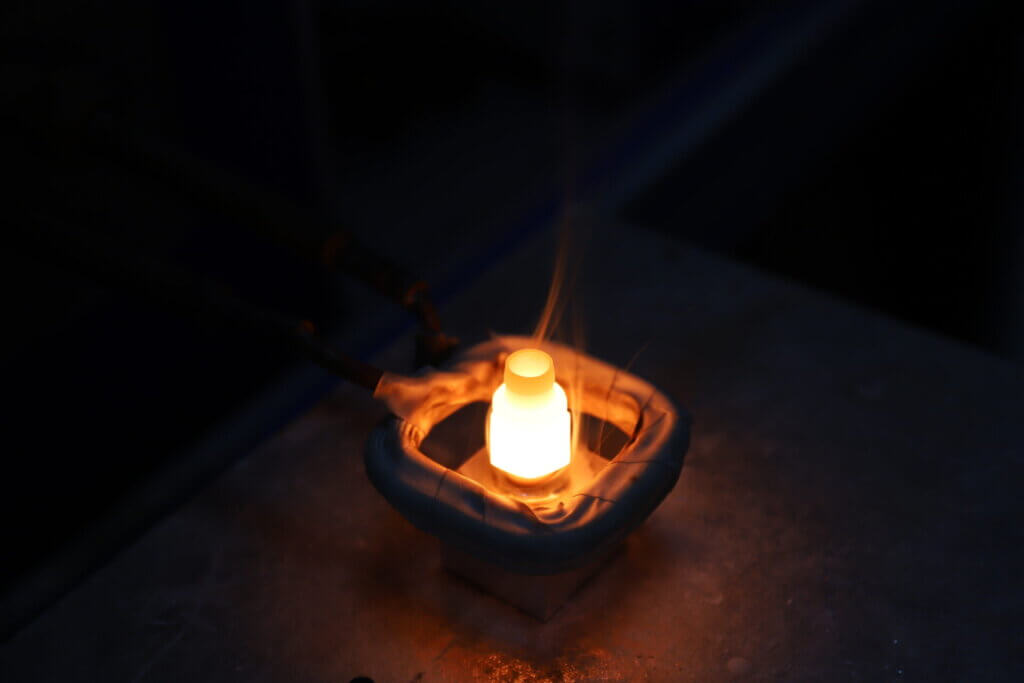

Common Applications

Joining metal parts (brazing, soldering).

Metal heat treatment (hardening, отжиг, shrink fitting).

Heating of metal before forging&forming or welding.

Melting metal for casting.

Why Choose Induction Heating?

It’s energy-saving, precise, and eco-friendly. By directly heating materials with electricity, it offers faster processing, better quality, and a cleaner working environment.

It’s energy-saving, precise, and eco-friendly. By directly heating materials with electricity, it offers faster processing, better quality, and a cleaner working environment.

Learn more about induction heating solutions on our website.

Хунчуанская высокая частота

Хунчуанская высокая частота