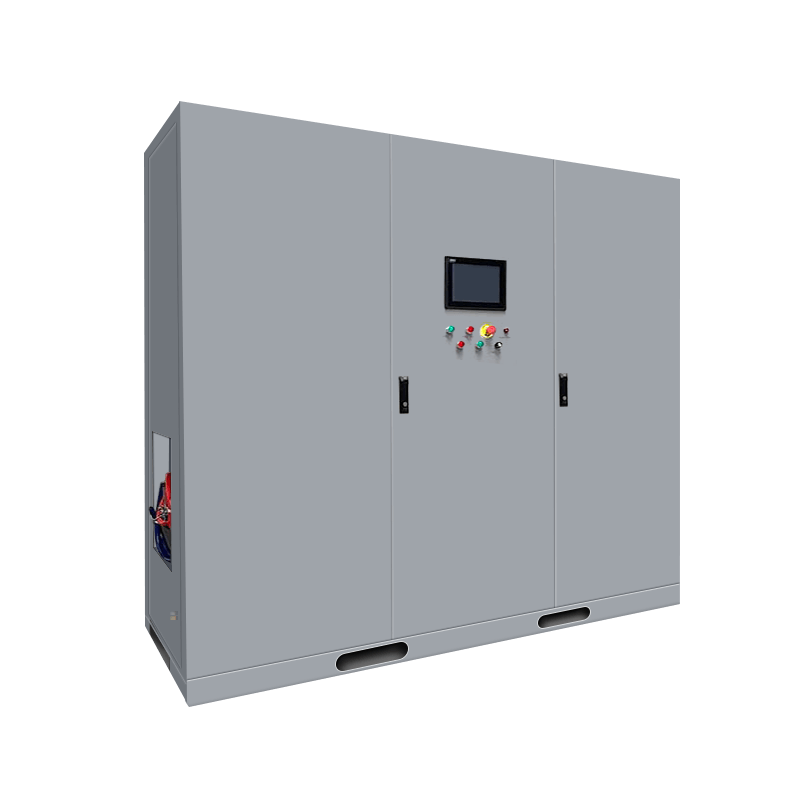

Features

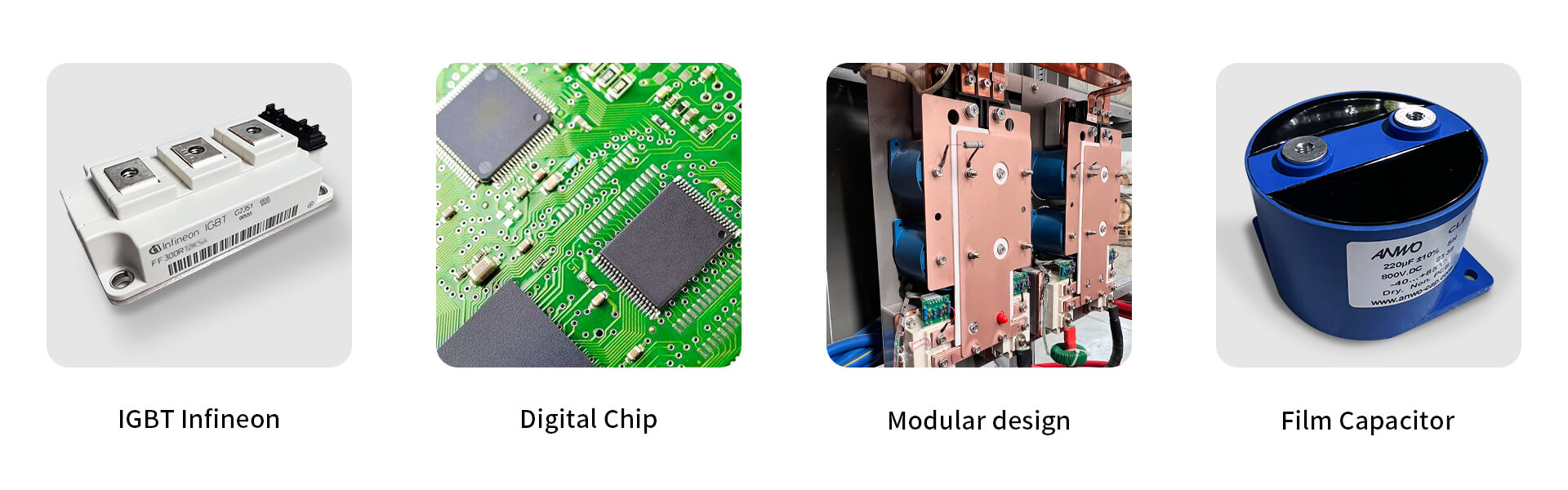

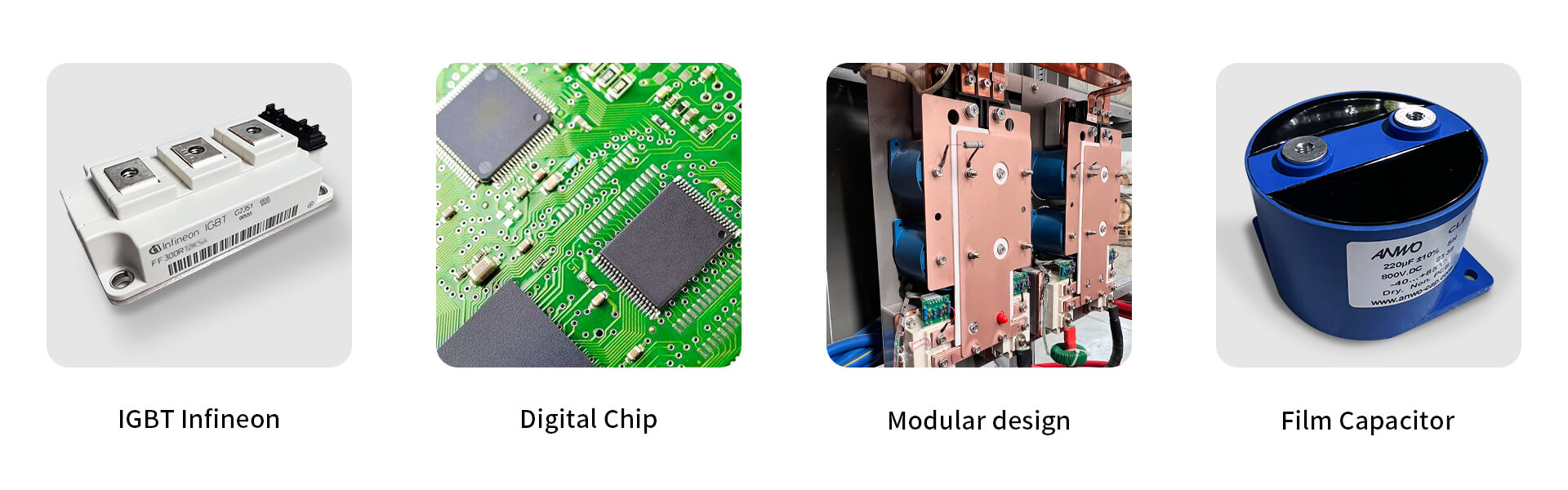

- High efficiency with IGBT inverter technology & LC series resonance circuit, enhances high efficiency.

- Digital chip technology, the control of power output and the detection of faults are entirely done through digital chip control, greatly reducing power variations or faults caused by environmental factors and usage time, enhances the reliability and stability of induction

- Modular design, with over 80% of components on module groups, allows for interchangeable module groups across all models, making maintenance and repair simple and convenient, while keeping costs low.

- HCGP Induction Generator can be designed as subharmonic resonance according to shape and material of the workpiece. Subharmonic resonance technology allows induction power supplyto have a wide range of impedance matching, induction heater can work with different coils at optimal operation during heating non-magnetic and irregularly shaped workpieces at high heating efficiency.

Advantages

- Energy saving 10%-30% comparing with SCR Transistors induction.

- High heating Efficiency increase production yield.

- Simple and practical equipment design, high cost-effectiveness.

- Induction Converter start heating under any load condition and operate at full load for 24 hours.

- Comprehensive the protection function ensuring high reliability of the induction equipment.

- Provide multiple signal transmission such as pulse signal, digital signal, RS-485 etc, HCGP induction heater is easier to integrated with other machine and achieve production automation.

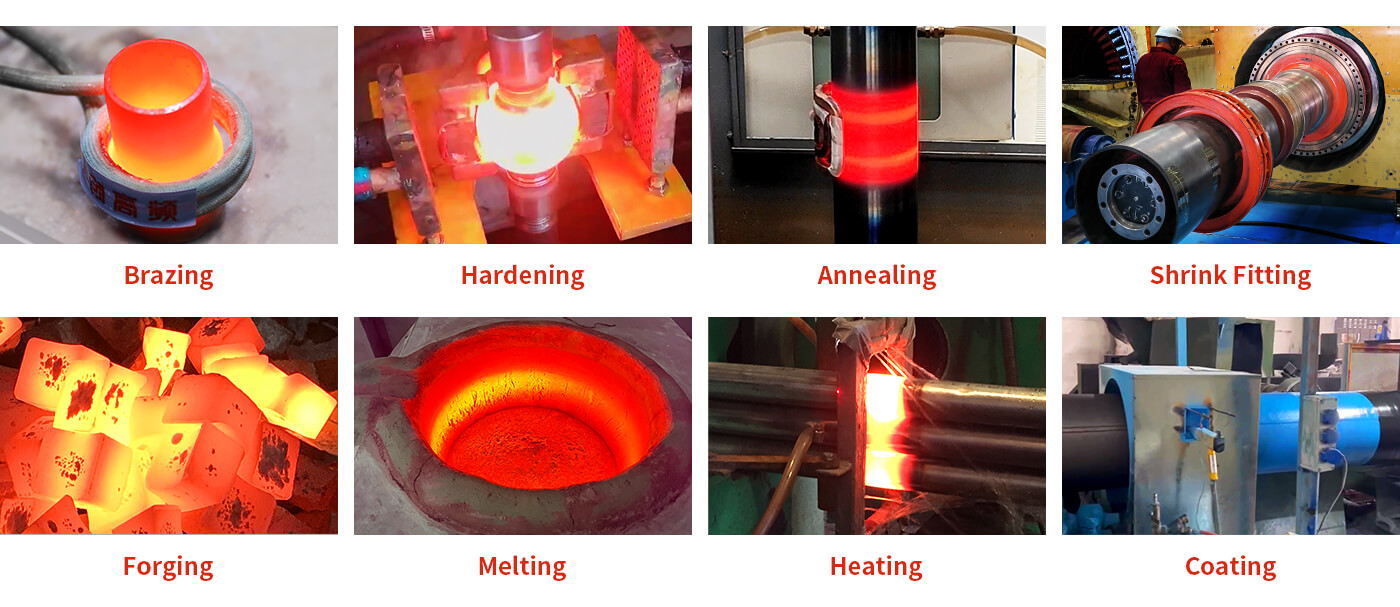

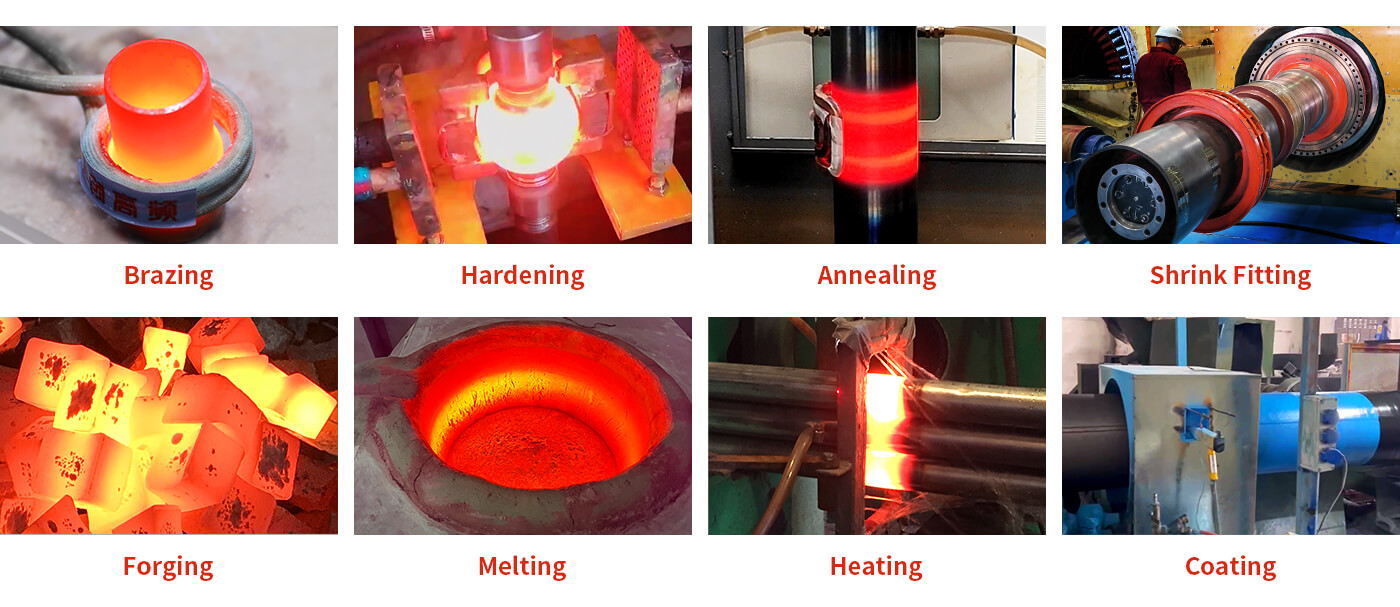

Application

Induction Forging & Forming, Induction Brazing, Shrink Fitting, Induction Hardening, Induction Heat Treatment, Induction Melting, Induction Coating

Our Customers

Application

Medium Frequency Induction Heating Equipment is good performance to heat larger work pieces or requirement of high production output. The applications as follow:

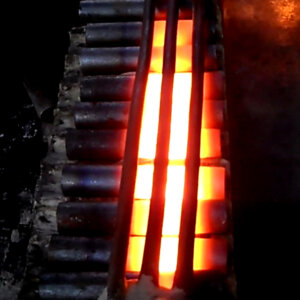

- Induction Forging & Forming

- Induction Brazing

- Induction Shrink Fitting

- Induction Hardening

- Induction Heat Treatment

- Induction Melting

- Induction Coating

- Induction Bending

Induction Brazing

Induction Shrink Fitting

Induction Forging

Induction Forming

1. How to choose the induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. The operation manual provides work standards for regular maintenance and guidance for dealing common fault. We also help you manage your spare parts inventory.

5. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

6. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

7. Can you help us design coil for our new produces?

We offer different coil service:

- Coil design with pre-purchase heating testing

- Coil design for different heating workpieces when purchasing induction equipment

- Coil design for customers when they developing new products

- Guide customers to make coils on their own

Induction Heating Coils

Hongchuang High Frequency

Hongchuang High Frequency