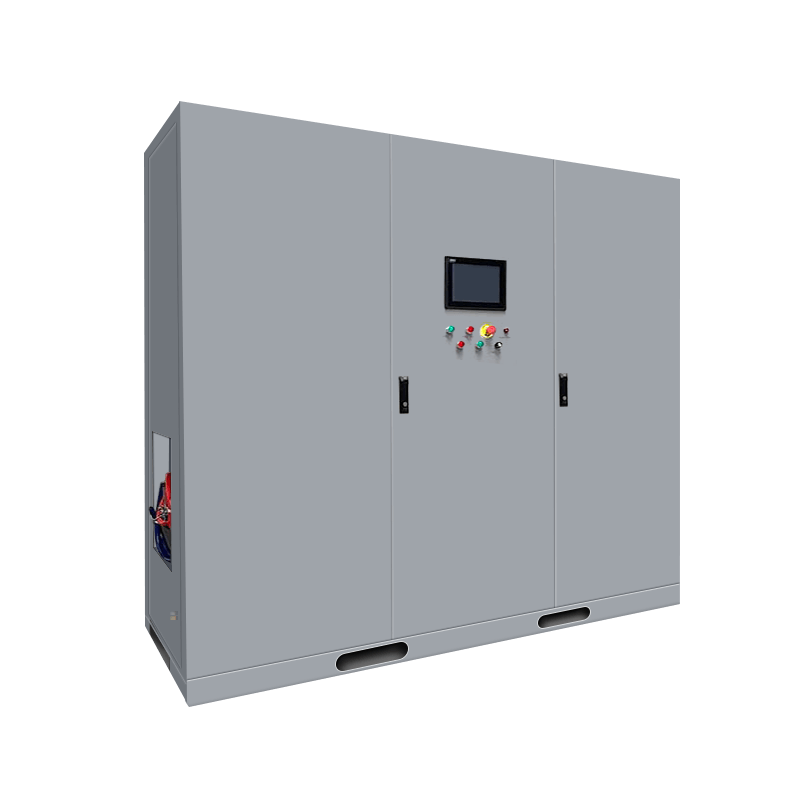

Features:

- MOSFET Inverter technology achieve ultra high frequency 50kHz-300kHz.

- IGBT wave chopping

- 100% load duration, 24-hour operation under maximum power;

- Power output regulation can be controlled by power or current.

- Working condition display: output power, frequency, current and voltage

- Accurate heating: Power control from 0-100%

- Working mode can be Automatic, Manual, Temperature Control (Optional)

- Comprehensive protection: Over current, over Temperature, Lack of water, Over Voltage, Phase Loss, Overheat.

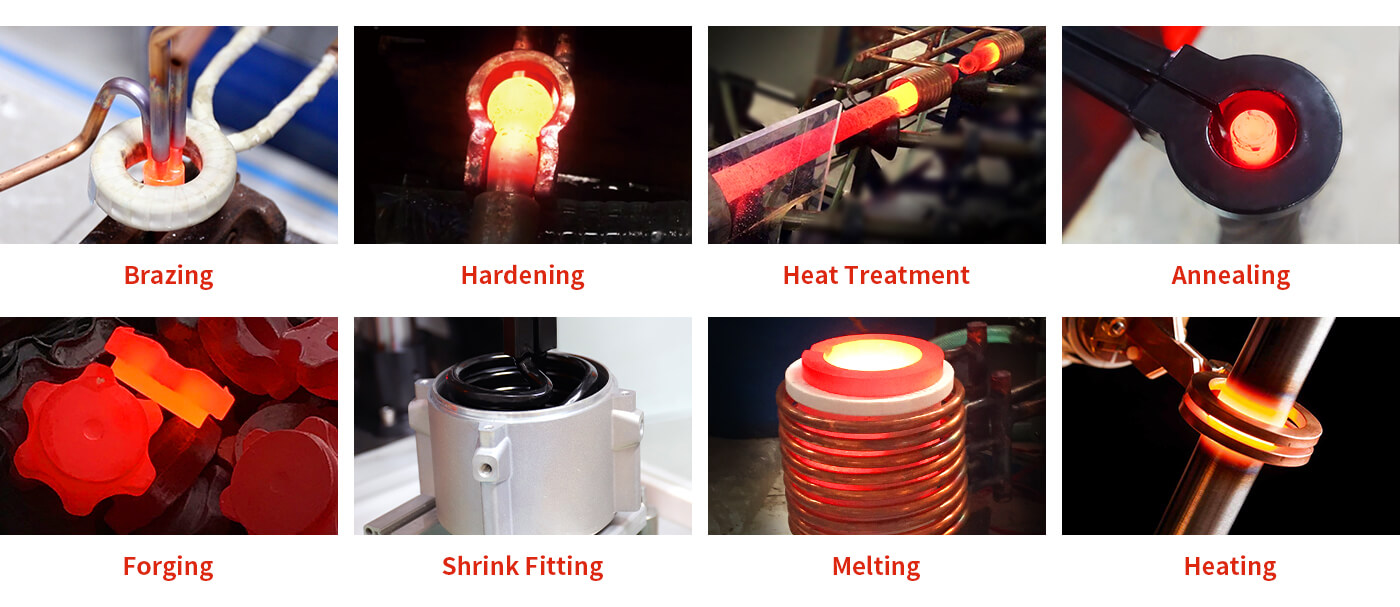

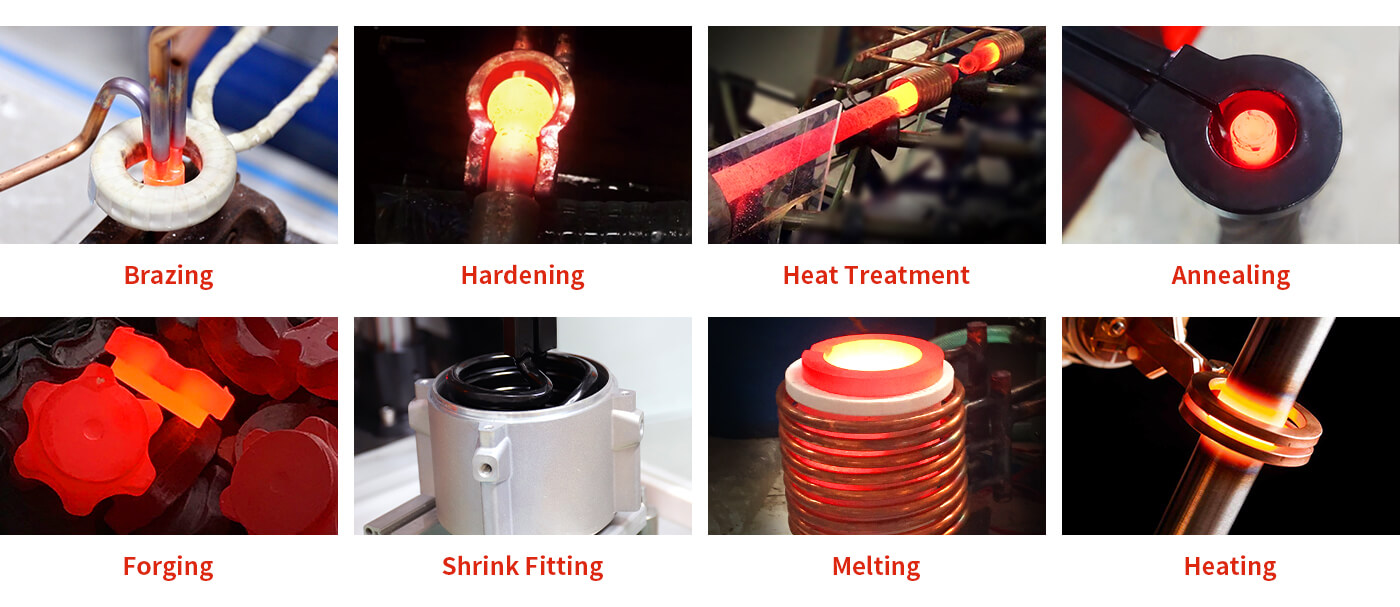

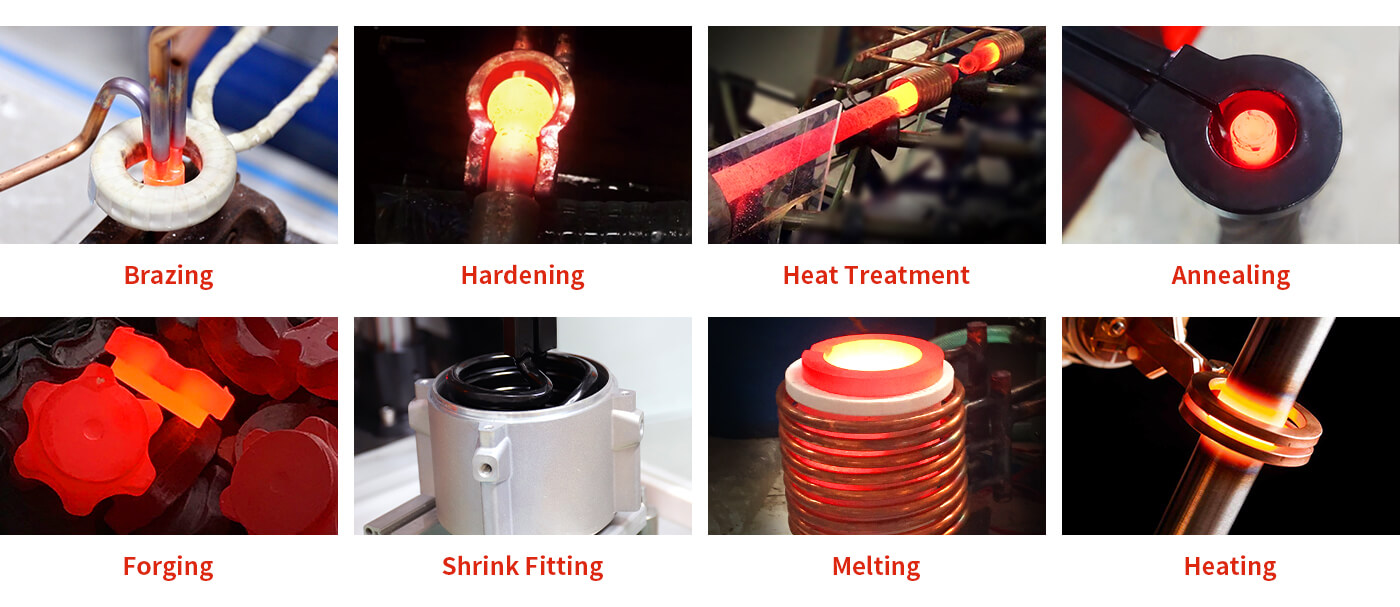

Application:

Induction Brazing, Shrink Fitting, Induction Hardening, Induction Annealing, Forging & Forming, Induction Melting, Induction Coating.

Advantages:

- Ultrahigh frequency (60kHz-200kHz), particularly suitable for small size workpieces heating. Ultra-fine metal in diameter 0.1mm can be brazing.

- Auto frequency scanning let heating coil work at high efficiency.

- Heating reliable and stable

- Heating without vibration, ensure accurate heating position.

Our Customers

Applications:

Ultra high frequency induction heating equipment is mostly used for surface quenching of industrial metal parts. It is a metal heat treatment method that generates a certain induction current on the surface of the workpiece, rapidly heats the surface of the part with high frequency and then rapidly quenches it. Ultrasonic frequency induction heating equipment, that is, equipment for induction heating of workpieces for surface quenching.

(1) Heat treatment of parts such as pinions and small shafts

(2) carbon steel screws and stainless steel screws heating viscose

(3) Maglev melting for schools and research institutes

(4) Smelting of crushed or powdered materials

(5) Copper pipe joint welding, etc.

- How to choose the induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

- Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

- How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

- The operation manual provides work standards for regular maintenance and guidance for dealing common fault. we also help you manage your spare parts inventory.

- How can customer get service when the machine get problem?

We provide 7×24 online technical support and repair service as well as on-site service.

- Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

- Can you help us design coilfor our new produces?

We offer different coil service:

- Coil design with pre-purchase heating testing,

- Coil design for different heating workpieces when purchasing induction equipment

- Coil design for customers when they developing new products

- Guide customers to make coils on their own

Induction Heating Coils

Packaging Details:

1. Wooden case for export

2. Adhesive wrap to prevent scratches

3. Plastic film to keep the machine together

4. Foam plate and block to prevent shake

5. Other customer’s requirements

Hongchuang High Frequency

Hongchuang High Frequency