Feature

- Induction Power Unit is air cooling, heating coil can be air cooling for some project, induction machine is more reliable with fault cause by water circuit.

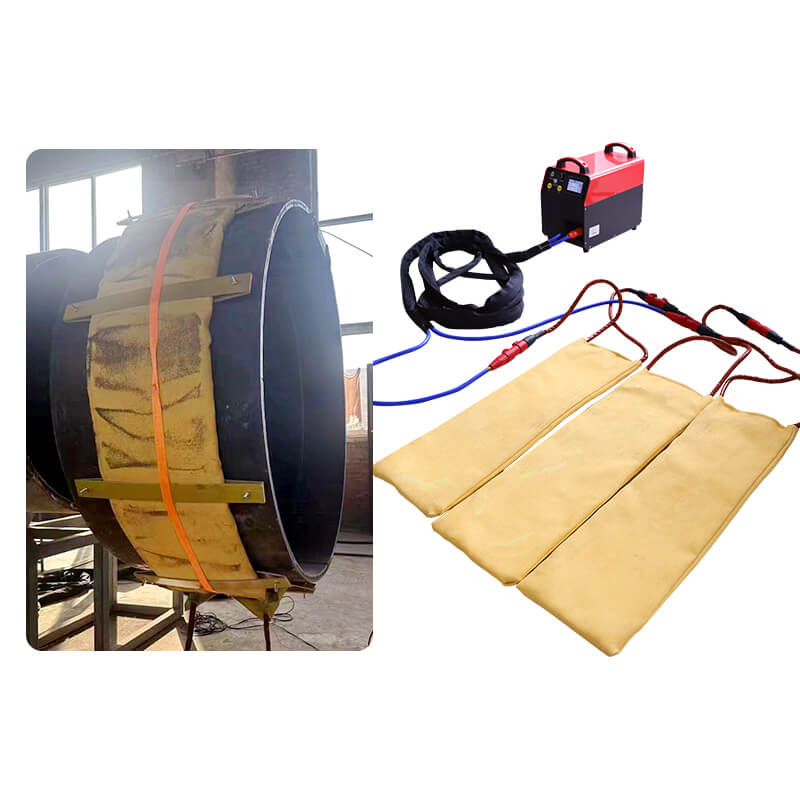

- The type of heating coil can be open type, curve, blanket, pad, with frame, adapt to a wide variety of work pieces for induction heating.

- Induction heating Device is equipped with wheels for easy movement

- Build-in Isolation output transformer for safer operation

- Parameter monitoring and display output power, current, frequency, temperature curve.

- Temperature measurement with k-type thermocouple, thermistor and infrared thermometer, the accurate can be 0.5℃.

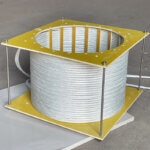

Heating Coil

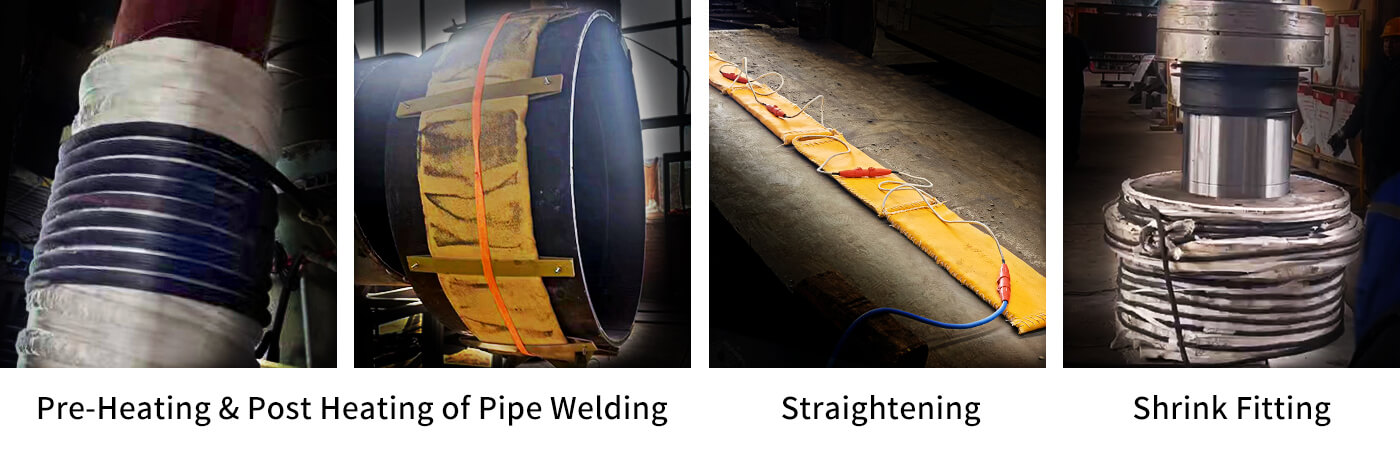

Application

Their main applications are pipeline heat, pre-weld heat, post-weld heat treatment, stress relief, injection mold heating, annealing, etc.

● Pre-heat:for coating, bending, fitting&unfitting, weld.

● Post-weld heat treatment: tank, boiler or other metal jobs

● Heating: mold heating, shipboard, zinc bath, large& irregular metal parts

● Pipeline heat: pipeline oil, pipeline gas, pipeline water, pipeline petrochemical and other pipeline material

The using fields involved are petrochemical, oil and gas pipelines, aerospace, shipbuilding, steel, tanks, boilers, vessels, pressure vessels, cylinders, metal structure, spatial structure, railway bridges, electricity water, mine construction, vehicle manufacturing, nuclear power, mining, plastics processing, energy saving process, mold, screw barrel

Our Clients

Hongchuang High Frequency

Hongchuang High Frequency