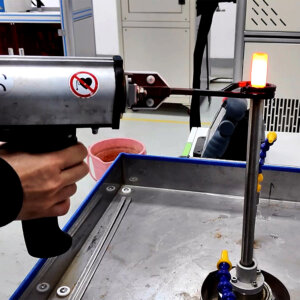

Mobile Induction Heating machine is induction generator work with handheld heating head for particularly heating process.

Advantages:

- Convenient Mobility: Handheld brazing equipment enables induction brazing for complex and hard-to-reach workpieces or workshop positions with small size, easy mobility, and simple operation.

- Good Controllability: The precise control of induction heating minimizes the risk of overheating during heating, avoiding damage to heated components and increase product qualification

- Precise Operation: Stable and vibration-free heating ensures accurate welding positions. It can weld metals with a minimum diameter of 0.1mm and the inductors can be customized according to the different shapes of workpieces.

- Convenient Operation: Induction heating can be processed at the places that store heating workpieces, just moving heating head for brazing or other process.

- Cost Reduction: Efficient and precise heating processes by induction ensure the qualification rate of welding, minimizing waste, rework, and energy consumption.

- Comfortable Working Environment: Induction heating is quiet and without causing a rise in the surrounding environment’s temperature.

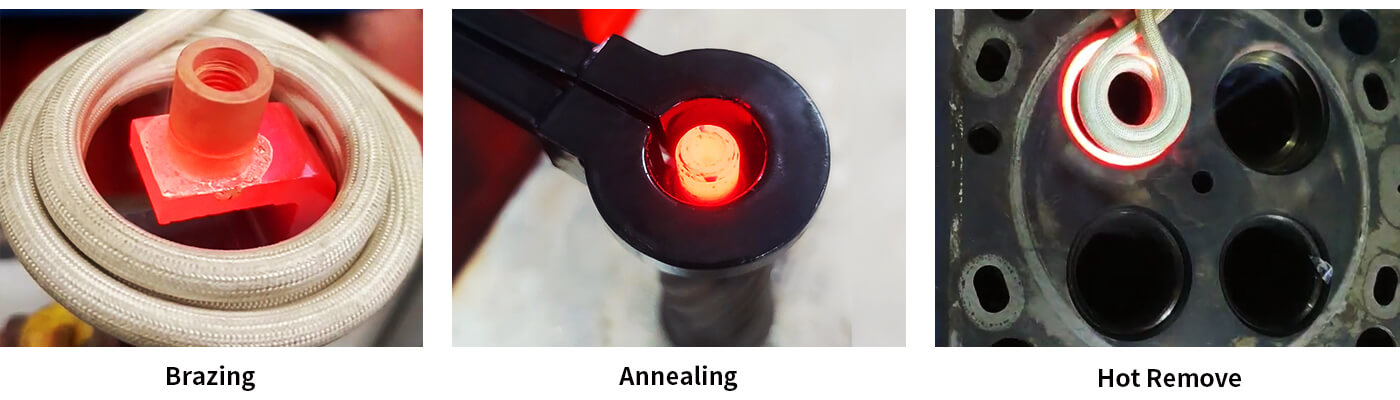

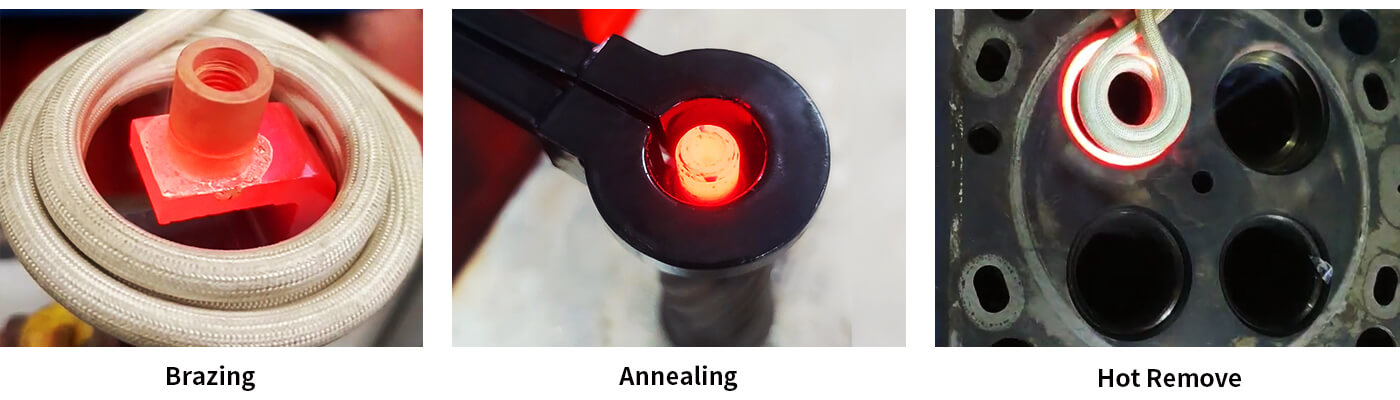

Application

o

Our Customers

Applications:

Potable induction heating device is widely applied in industries such as refrigeration and HVAC, household appliances, automobile manufacturing, electrical motor, and medical devices. Induction heating equipment integrated with chiller let installation and operation more convenience.

Mobile Induction Brazing

Copper Induction Brazing

Steel Bar Induction Heating

Induction Brazing

1. How to choose the induction heating machine?

Please tell us with the dimensions and heating area of workpiece, heating temperature and heating time, as well as any specific requirement of heating process, our experience sales will recommend the appropriate induction heating equipment.

2. Can we see the heating test before purchase induction heater?

Customs can send the workpiece to us for heating testing in our laboratory, and decide whether purchase HCGP induction machine after received the heating testing video and report.

3. How about the service of installation and commission?

The details manual and guide for installation and commission with picture and video will be sent to our customers. Most of our customers can complete installation and commission on their own follow our instructions. We still provide paid on-site installation service.

4. How can customer get service when the machine get problem?

We provide 7x24h online technical support and repair service as well as on-site service.

5. Can you provide repair parts for a long time?

Yes, we will help our customer manage their spare parts inventory.

6. Can you help us design coil for our new produces?

We offer different coil service:

- Coil design with pre-purchase heating testing

- Coil design for different heating workpieces when purchasing induction equipment

- Coil design for customers when they developing new products

- Guide customers to make coils on their own

Induction Heating Coils

Hongchuang High Frequency

Hongchuang High Frequency