Feature

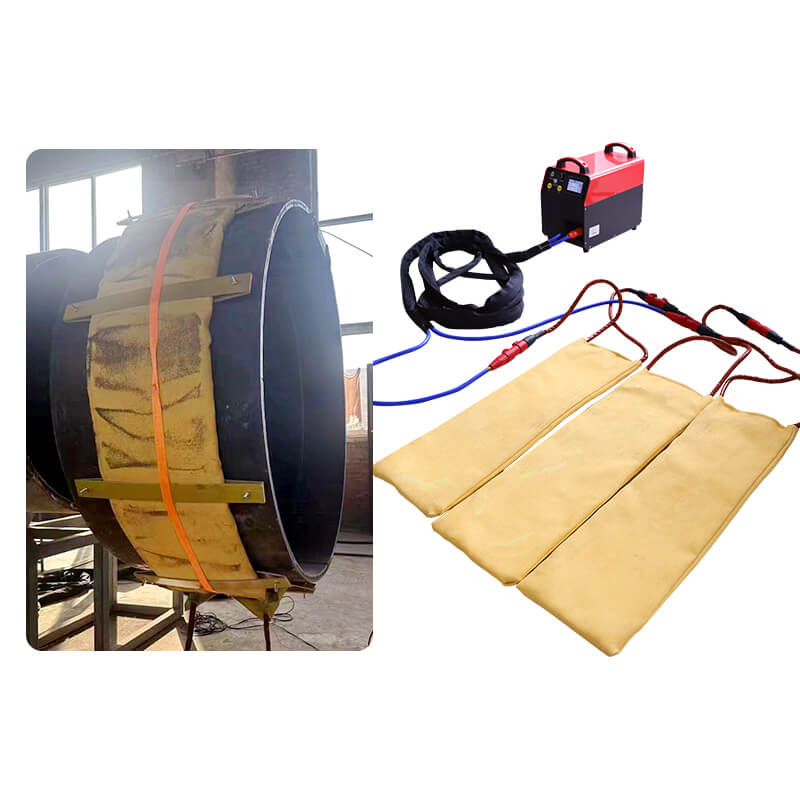

- Integrated design, easy installation and movement for outdoor working.

- Portable with lightweight

- Convenient, practical and cost-effective

- Isolation output transformer for safer operation;

- HMI with multiple heating modes setting

- Machine is air-cooling without fault cause by water channel problem, reduce failure rate.

- Full working load factor more than 90%;

- Three temperature measurement methods: K-type thermocouple, thermistor and infrared temperature measurement, up to 28 channels setting, the measurement accuracy can be 0.5℃;

- Simple operation with 7 inch touch screen, which display power, current, frequency, real-time curves of temperature, and temperature curve can be read with a USB flash drive;

- Heating coil can be customized regarding to workpiece and process, such as: opening and closing coil, coil with frame, coils can be flat, curved, strip.

- PID temperature closed-loop control, can realize multi-stage curve heating and heat preservation

Application

Induction air cooling heating equipment are widely used in automatic preheating of circumferential seam welding, anti-corrosion coating, offshore platform welding, hot disassembly and assembly of rotors, Hydrogen removal after welding, metal heating, post-weld heat treatment, straightening, shrink sleeve, heat removal, heat penetration, crystal growth, and hot coating.

Our Clients

Hongchuang High Frequency

Hongchuang High Frequency