Feature

- Induction Power Unit is air cooling, heating coil can be air cooling for some project, induction machine is more reliable with fault cause by water circuit.

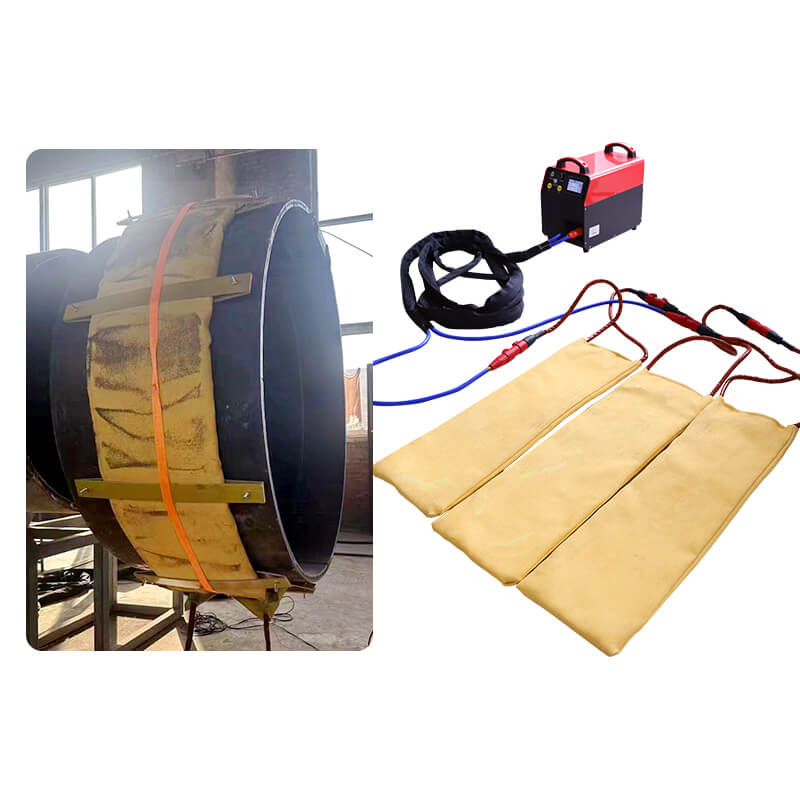

- The type of heating coil can be open type, curve, blanket, pad, with frame, adapt to a wide variety of work pieces for induction heating.

- Induction heating Device is equipped with wheels for easy movement

- Build-in Isolation output transformer for safer operation

- Parameter monitoring and display output power, current, frequency, temperature curve.

- Temperature measurement with k-type thermocouple, thermistor and infrared thermometer, the accurate can be 0.5℃.

Various Induction Coil

Application

Air Cooling induction heating system has superior performance for various special metal heating process, such as preheating before welding and heat treatment after welding of special steels which are an important application field of induction heating. Preheating steel before welding can reduce stress, improve welding strength, and prevent cracking. Post-heating is used for processes such as Hydrogen removal after welding, annealing, tempering, and normalizing.

Hongchuang High Frequency

Hongchuang High Frequency

We looking for induction heater suitable die heating upto 200 to 300 degree Celsius (1000*1000*1000 to100*100*50 mm size / weight 20 to 200 kg) it should be movable, easy to and unload the die.

Hello,this is Lydia,i have sent email to you,please check